Адрес

304 Северный кардинал

Улица Дорчестер Сентер, MA 02124

Рабочие часы

Понедельник - пятница: 7AM - 7PM

Выходные: 10AM - 5PM

Адрес

304 Северный кардинал

Улица Дорчестер Сентер, MA 02124

Рабочие часы

Понедельник - пятница: 7AM - 7PM

Выходные: 10AM - 5PM

Struggling with getting precise aluminum parts? I know how frustrating poor quality can be, impacting your entire project schedule. Custom CNC aluminum offers a path to consistent results and might be the exact solution you need.

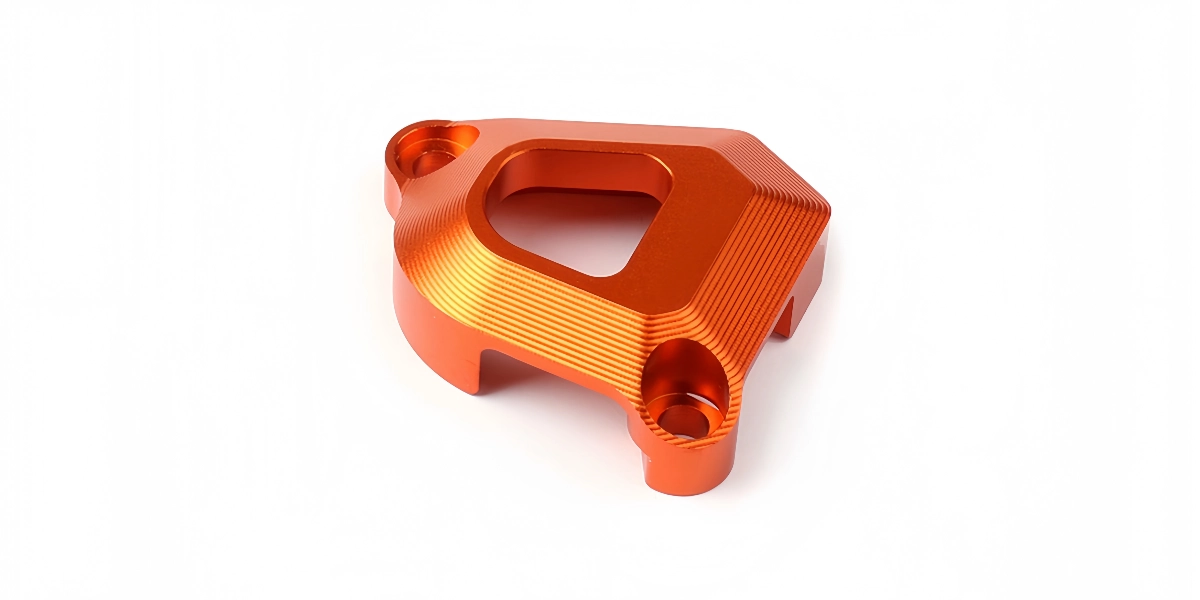

From my experience running ALUT, I see flawless custom CNC aluminum as the ultimate secret because it delivers unparalleled precision exactly to your designs. This control over complex shapes and tight tolerances ensures your components fit perfectly, boosting your product’s performance and reliability every time.

But what does this process really involve, and what makes it so effective? Let’s break down the specifics so you can see how custom CNC aluminum can work for you and potentially streamline your sourcing for those critical components.

Confused by the term “CNC”? Maybe you’ve heard it tossed around but aren’t quite sure what it means for aluminum parts specifically. It can sound technical, but understanding the basics really helps in getting the best possible components for your products.

I explain custom CNC aluminum machining simply: it’s using computer-controlled machines to precisely cut, shape, and finish aluminum blocks or bars based on your digital design files. Think of it as a highly accurate, automated sculptor specifically for metal parts.

Let’s dive a bit deeper into what makes custom CNC aluminum machining tick. At its core, CNC stands for Computer Numerical Control. This means a computer program directs the movements of the machinery. There’s no manual lever pulling or guesswork involved in the cutting path; it’s all dictated by code derived from your design.

The process starts long before the machine starts cutting. It begins with a digital design, usually created in CAD (Computer-Aided Design) software. This file contains all the geometric information about the part. Your engineers might create this, or sometimes design houses do. The key is having a precise digital blueprint.

Next, this CAD file is loaded into CAM (Computer-Aided Manufacturing) software. This is where the magic of translation happens. The CAM software calculates the optimal toolpaths – the exact routes the cutting tools will take across the aluminum stock. It considers factors like tool type, cutting speed, feed rate, and the specific aluminum alloy being used. The output from the CAM software is typically G-code, which is the specific programming language that CNC machines understand. This code tells the machine exactly where to move, how fast, and when to turn tools on or off.

While there are various types, typical CNC machines used for custom CNC aluminum parts (like mills or lathes) share core components:

It’s important to understand that custom CNC aluminum machining is a subtractive process. This means we start with a solid piece of material (the aluminum stock) and remove material strategically to arrive at the final desired shape. This is different from additive manufacturing (like 3D printing) where the material is added layer by layer. Subtractive methods like CNC machining are often preferred for metal parts requiring high strength, specific material properties, and tight tolerances, which are hallmarks of custom CNC aluminum production. The precision comes from the machine’s ability to remove material exactly where the program dictates, often down to thousandths of an inch.

Need strong but lightweight parts for your products? Maybe you’re tired of the design limitations you face with standard, off-the-shelf components. Poor part quality or inconsistency can definitely hold back production and hurt your reputation.

In my view, the core benefits of custom CNC aluminum are precision, repeatability for large orders, design freedom for complex shapes, and leveraging aluminum’s great strength-to-weight ratio. It directly solves many manufacturing headaches I see purchasing managers face with demanding applications.

Let’s unpack these benefits further, as they are crucial for buyers like you who need reliable parts for assembly into larger products.

This is often the number one reason companies turn to custom CNC aluminum. CNC machines operate based on precise digital instructions. This eliminates the variability found in manual processes. We can consistently achieve very tight tolerances, meaning the dimensions of the finished parts will be extremely close to your design specifications. This is critical when parts need to fit together perfectly in an assembly, like in electronic enclosures or complex machinery. Consistent accuracy reduces rejects and assembly problems downstream.

Unlike processes like casting or extrusion which have geometric limitations, CNC machining allows for highly complex shapes and intricate details. Undercuts, complex curves, thin walls, and fine features can often be produced effectively. This gives your engineers more freedom to design parts optimized for function, weight, or aesthetics, rather than being constrained by manufacturing limitations. If you can design it in CAD, chances are good we can machine it using custom CNC aluminum techniques.

Once the program is proven and the machine is set up, CNC machines can produce identical parts quickly and efficiently. This repeatability is essential for volume production. Every part in a batch will be virtually identical to the first, ensuring consistency in your final product. While the initial setup might take time, the per-part production speed is often very fast, making custom CNC aluminum cost-effective for medium to high-volume runs.

Aluminum itself offers fantastic properties – it’s lightweight, strong for its weight, naturally corrosion-resistant, electrically conductive, and easily recyclable. Custom CNC aluminum machining allows you to leverage these inherent benefits while shaping the material exactly as needed. Different alloys offer variations (more strength, better corrosion resistance, etc.), allowing you to select the perfect balance for your application.

Here’s a quick summary table of these key benefits:

| Выгода | Пояснение | Why it Matters for You |

| Точность | Achieves very tight dimensional tolerances based on digital designs. | Ensures parts fit correctly, reducing assembly issues & rejects. |

| Repeatability | Produces virtually identical parts across entire production runs. | Guarantees consistency in your final products. |

| Сложность | Can create intricate shapes, fine details, and complex geometries. | Allows for optimized designs without manufacturing constraints. |

| Material Choice | Leverages aluminum’s inherent benefits (strength-to-weight, corrosion resist). | Provides durable, lightweight, and functional components. |

Choosing custom CNC aluminum means choosing control, consistency, and the ability to get the exact part you need, reliably.

Ever wondered how a digital file on a computer screen actually becomes a physical metal part in your hands? Sometimes the manufacturing process can seem like a bit of a black box. Understanding the steps involved helps ensure better communication and collaboration with suppliers like us at ALUT.

I oversee this transformation daily at ALUT. The custom CNC aluminum process fundamentally starts with your design (usually a CAD file), moves to programming (CAM software creating toolpaths), then involves machine setup, the actual cutting and shaping on the CNC machine, and finally, essential finishing touches and quality checks.

Let’s walk through these stages in a bit more detail, so you have a clearer picture of how your custom CNC aluminum parts come to life.

Everything begins with the design. You or your engineering team will create a 2D or 3D model of the part using CAD software. Common file formats we work with include STEP, IGES, DWG, or DXF. The accuracy and completeness of this CAD file are critical. It needs to clearly define all dimensions, tolerances, required features, and any specific surface finish requirements for the custom CNC aluminum part. A well-defined CAD model minimizes misunderstandings and potential errors later on.

Once we have your approved CAD file, our engineers use CAM software. This software acts as the bridge between the design and the physical machine. It interprets the CAD model and helps the programmer determine the best machining strategy. This includes selecting the right cutting tools, setting cutting speeds and feed rates, and generating the optimal toolpaths (the precise route the tools will follow). The output of this stage is the G-code – a set of instructions the CNC machine controller understands.

Before any cutting begins, the CNC machine must be properly prepared. This involves several key tasks:

This is where the action happens. The machine operator loads the G-code program into the CNC controller and initiates the cycle. The machine then automatically executes the programmed instructions:

After the main machining is complete, the custom CNC aluminum part usually requires some final steps:

Here’s a simplified table outlining the workflow:

| Step # | Stage | Key Action | Output / Result |

| 1 | Design (CAD) | Create precise 2D/3D digital model | Approved CAD file (STEP, IGES, etc.) |

| 2 | Programming (CAM) | Generate toolpaths & machine instructions | G-code program |

| 3 | Machine Setup | Secure aluminum stock, load tools, set offsets | Machine ready for operation |

| 4 | Machining | Execute G-code, cut material automatically | Raw machined part |

| 5 | Finishing & QC | Deburr, apply finishes, inspect dimensions | Finished, verified custom CNC aluminum part |

Understanding this structured process helps you appreciate the precision involved in creating high-quality custom CNC aluminum components.

Choosing the right material can feel overwhelming sometimes, can’t it? You worry that picking the wrong aluminum alloy might compromise the performance or longevity of your final product. Selecting the most suitable alloy is key to getting the best results from custom CNC aluminum machining.

From our factory experience at ALUT, alloys like 6061 (highly versatile, great machinability), 7075 (excellent strength for demanding applications), and 5052 (superior corrosion resistance, especially in marine environments) are frequent stars for custom CNC aluminum parts. Honestly, the “best” alloy truly depends on your specific application’s requirements – strength, weight, environment, and cost.

Let’s explore some of the most common and effective aluminum alloys used in custom CNC aluminum machining, considering factors that matter to purchasing managers and engineers.

Before diving into specific alloys, consider what properties are most important for your part:

This is arguably the most popular alloy for custom CNC aluminum machining, and for good reason.

When maximum strength is the priority, 7075 is often the go-to choice.

If the part operates in a wet or corrosive environment, 5052 shines.

Here’s a comparative table for quick reference:

| Сплав | Key Feature | Common Use Category | Machinability | Устойчивость к коррозии | Относительная сила |

| 6061 | Versatile All-Rounder | General Purpose, Structural | Good | Good | Средний |

| 7075 | Highest Strength | Aerospace, High-Stress | Fair | Poor | Очень высокий |

| 5052 | Excellent Corrosion Res | Marine, Sheet Metal | Good | Excellent | Medium-Low |

| 2024 | Высокая прочность | Аэрокосмическая промышленность | Good | Poor | Высокий |

Ultimately, discussing your specific application requirements with your supplier is the best way to select the optimal alloy for your custom CNC aluminum needs. We can guide you based on performance needs and budget.

In short, custom CNC aluminum provides remarkable precision and design flexibility for your critical components. Understanding the straightforward process and the common material choices helps ensure you get reliable parts for smoother projects.