Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

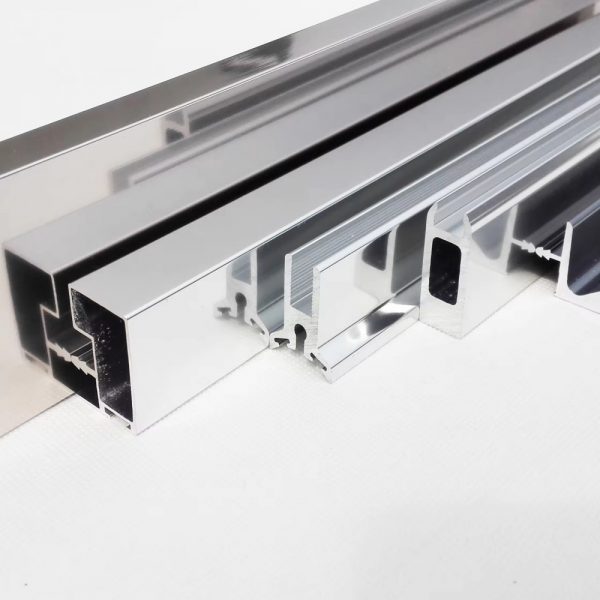

Polished aluminum provides a visually appealing and robust material choice. This guide explores the advantages of polished aluminum, differentiating it from brushed aluminum in terms of appearance and application. Discover effective methods to preserve its luster, ensuring longevity and aesthetic appeal. Ideal for decorative trims, automotive parts, and more, understanding the maintenance and benefits of polished aluminum is crucial for various industrial and consumer applications. Learn more about keeping polished aluminum shiny and durable!

I’ve always been fascinated by shiny things. Polished aluminum is one of them! Let’s explore why it’s so cool.

I think polished aluminum is great because it looks awesome and it’s strong. It also doesn’t rust, so it lasts a long time. This makes it a good choice for many different uses. I use it every day in my factory.

So, what exactly makes polished aluminum so special? Let’s dive in and find out more.

Why choose polished aluminum? It has some clear advantages! I’ll tell you what they are.

I find the biggest benefit is its look. It’s super shiny and modern. Plus, it’s strong but lightweight. This makes it useful for things like car parts and even phone cases. I’ve seen it used everywhere.

Let’s break down the benefits of polished aluminum a bit more. We can look at this from a few angles, okay?

The look of polished aluminum is a big draw. It has a clean, modern, and reflective surface. This makes it popular for decorative uses. But what about the details?

| Feature | Description |

| Reflectivity | Polished aluminum can reflect a lot of light. This makes things brighter and more visually appealing. |

| Modern Look | It gives a sleek and modern feel. This is why it’s often used in contemporary designs. |

| Smooth Surface | The polishing process makes the surface very smooth. This makes it nice to touch and easy to clean. |

Aluminum naturally resists rust. But polishing it adds even more protection. This is important for outdoor uses. Here are some things to consider:

Natural Oxide Layer: Aluminum forms a natural layer of oxide that protects it.

Polishing Enhancement: Polishing makes this layer even stronger.

Weather Resistance: This is great for things exposed to rain and sun.

Aluminum is strong, but it’s also light. This is super helpful in many situations. Here’s why this matters:

Lightweight: It doesn’t add a lot of extra weight to a product.

Strong: It can still handle a lot of stress and pressure.

Efficiency: This combination makes it energy-efficient for vehicles and machines.

Besides these, there are other things that make polished aluminum good.

Recyclable: Aluminum is easy to recycle, making it eco-friendly.

Durable: It lasts a long time, so it’s a good investment.

Versatile: You can use it for lots of different things, from cooking pots to airplane parts.

So, all these benefits together make polished aluminum a really smart choice for many different projects. I see it as a win-win material. It looks good and works great.

Polished or brushed aluminum? What’s the real difference? Let me clarify things for you.

I think the main difference is the finish. Polished aluminum is super shiny, like a mirror. Brushed aluminum has lines on it and is less shiny. I usually pick polished when I want something to look fancy.

To understand the difference, let’s break it down. It’s not just about looks; it’s also about how they are made and used.

This is the most obvious difference. One is shiny, and the other isn’t.

Polished: Very reflective, mirror-like finish. This is achieved by using abrasive compounds to smooth the surface until it shines.

Brushed: Has a satin finish with fine lines going in one direction. This is made by using brushes or abrasive pads to create a textured surface.

How they are made changes their properties too.

Polishing: This involves a series of steps. First, you grind down the surface. Then, you use finer and finer materials to polish it. The goal is to make it as smooth as possible.

Brushing: This is simpler. You run a brush or abrasive pad across the surface. This creates the lines that give it the brushed look.

Because of their looks and properties, they are used differently.

| Feature | Polished Aluminum | Brushed Aluminum |

| Common Uses | Decorative trims, mirrors, reflectors, high-end appliances | Appliance exteriors, architectural panels, automotive trim |

| Aesthetic | High-gloss, reflective, modern | Subtle, matte, industrial |

| Maintenance | Shows fingerprints and scratches more easily, requires regular cleaning to maintain shine | Hides fingerprints and scratches better, requires less frequent cleaning |

Besides looks, there are practical things to think about.

Maintenance: Polished aluminum needs more cleaning to keep it shiny. Brushed aluminum hides dirt better.

Cost: Polishing is often more expensive because it takes more time and effort.

Scratch Resistance: Brushed aluminum hides scratches better than polished.

In my factory, I consider all these factors before choosing one. For decorative parts, I go with polished. For something that needs to handle wear and tear, I use brushed. It all depends on the job.

Want to keep your polished aluminum looking great? It needs some care! I’ve got some tips for you.

I think the key is regular cleaning. Use a soft cloth and some mild soap. Avoid anything harsh that could scratch it. I also use a special aluminum polish sometimes to keep it extra shiny.

Keeping polished aluminum shiny isn’t too hard, but you need to do it right. Let’s talk about how to prevent damage and keep it looking its best.

The first step is to clean it often.

Frequency: Wipe it down weekly or bi-weekly to remove dust and dirt.

Tools: Use a soft microfiber cloth to avoid scratches.

Soap: Use mild dish soap mixed with water. Avoid harsh chemicals.

Sometimes, soap and water aren’t enough.

Aluminum Polish: Use a polish made for aluminum. Follow the directions on the bottle.

Application: Apply the polish with a clean cloth. Rub gently in circular motions.

Buffing: Buff the surface with a clean, dry cloth until it shines.

Preventing scratches is better than trying to fix them.

| Prevention Method | Description |

| Avoid Abrasives | Don’t use abrasive cleaners or scrub brushes. These can scratch the surface. |

| Protect the Surface | If the item is in a high-traffic area, consider applying a protective coating. |

| Handle with Care | Be careful when handling polished aluminum to avoid dropping or scratching it. |

If you get scratches, don’t panic.

Minor Scratches: Use a fine-grade polishing compound. Rub gently until the scratch disappears.

Deep Scratches: For deeper scratches, you may need to sand the surface lightly before polishing. This is best left to professionals.

Here are some other things I’ve learned over the years.

Wax: Applying a thin coat of wax can protect the surface and make it easier to clean.

Storage: Store polished aluminum items in a clean, dry place to prevent corrosion.

By following these steps, you can keep your polished aluminum looking shiny for years. It’s all about regular care and using the right products.

Polished aluminum is great for its looks and strength. Taking care of it keeps it shining.