Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

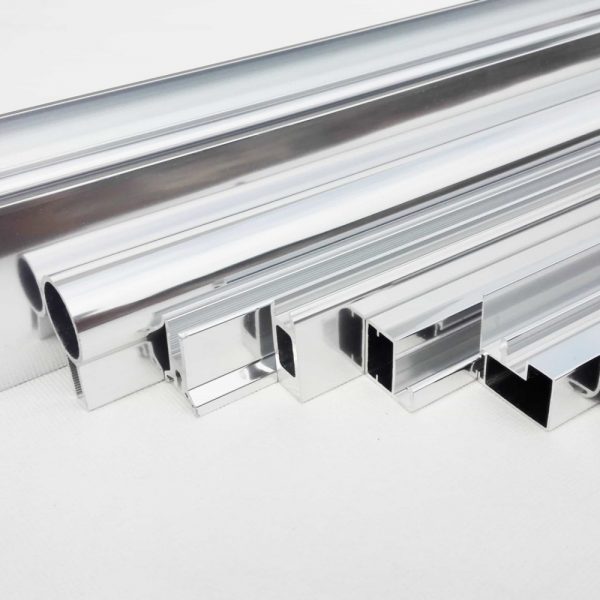

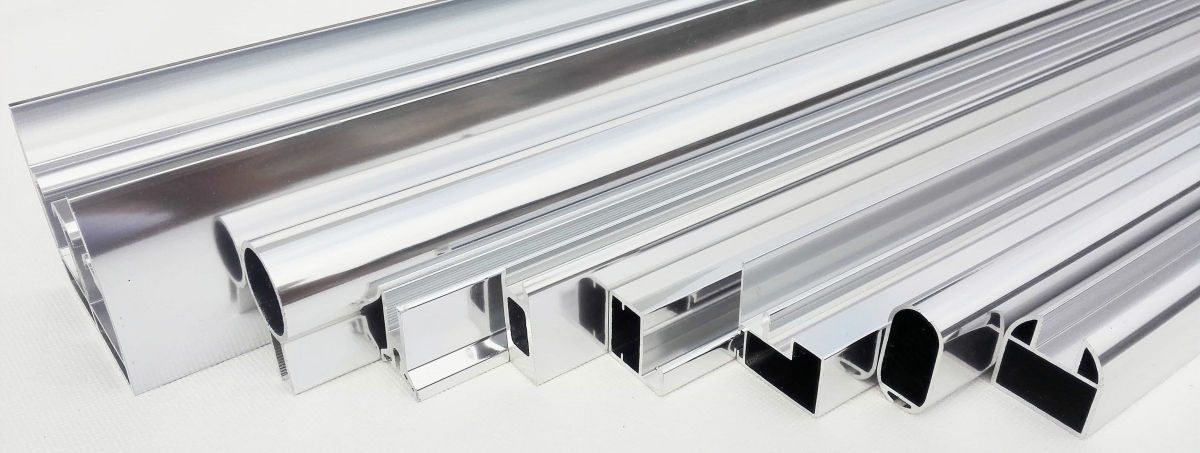

Mirror polish aluminum delivers an exceptional reflective surface for various applications. This article explores why aluminum is ideal for mirror polishing and outlines the necessary steps to achieve this high-gloss finish. Discover its uses in decorative trims, reflectors, and premium appliances, highlighting its aesthetic and functional benefits. Learn about alloy selection and the importance of precise polishing techniques. Understand how mirror polish aluminum enhances both visual appeal and performance in diverse industries. Explore the benefits of mirror polish aluminum today!

I love seeing how reflective we can make aluminum. Mirror polishing takes it to the next level! Let’s explore.

Mirror polish aluminum is when aluminum is polished to a super high shine, almost like a mirror. The surface becomes so smooth that it reflects light perfectly. In my factory, we use specialized techniques to achieve this level of reflectivity, and it’s always impressive to see the final result.

So, what makes mirror polish aluminum so special? Let’s find out.

Why is aluminum a good choice for mirror polishing? I’ll explain the key reasons.

I think its natural properties make it a great candidate. Aluminum is soft enough to be easily polished, but it’s also strong enough to hold its shape. I’ve also noticed that some alloys work better than others for achieving that perfect mirror finish.

Let’s take a deeper look into the properties that make aluminum suitable for mirror polishing. Understanding these characteristics will help you appreciate why it’s a preferred material for this process.

Aluminum is relatively soft compared to other metals.

Easy to Shape: This softness allows it to be easily shaped and polished.

Reduced Effort: Requires less effort to achieve a smooth surface.

Faster Polishing: Reduces the time needed for the polishing process.

Aluminum naturally resists corrosion.

Protective Layer: Forms a protective oxide layer that prevents rust.

Long-Lasting Shine: Helps maintain the mirror finish for a longer time.

Low Maintenance: Requires less maintenance to keep the surface looking good.

Aluminum is lightweight but still strong.

| Property | Description | Benefit |

| Lightweight | Easy to handle and work with. | Makes it ideal for applications where weight is a concern. |

| High Strength | Can withstand stress without deforming. | Ensures the polished surface remains smooth and undamaged. |

| Durable | Long-lasting and resistant to wear. | Provides a mirror finish that lasts for a long time. |

Certain aluminum alloys are better suited for mirror polishing than others.

5052 Alloy: Offers good corrosion resistance and polishability.

6463 Alloy: Strong and can be polished to a high shine.

1100 Alloy: Pure aluminum, very soft and easy to polish.

In my experience, selecting the right alloy is crucial for achieving the best results. Some alloys simply respond better to the polishing process than others.

What does it take to get that perfect mirror finish? I’ll walk you through the steps we use.

I think the process usually starts with grinding to remove any imperfections. Then, we use progressively finer polishing compounds to smooth the surface. Finally, we buff it to a high shine. Each step is crucial for achieving that mirror-like finish.I think the process usually starts with grinding to remove any imperfections.

Let’s break down the steps involved in mirror polishing aluminum. Each step is essential for achieving that flawless, reflective surface.

The first step is to remove any surface imperfections.

Coarse Abrasives: Use coarse abrasives to remove scratches, dents, and other defects.

Smooth Surface: Create a smooth surface as a base for polishing.

Prepare for Polishing: Get the surface ready for the next steps in the process.

This step involves using finer abrasives to further smooth the surface.

| Step | Description | Purpose |

| Finer Abrasives | Switch to finer abrasives, such as polishing compounds. | Remove scratches left by the coarser abrasives. |

| Multiple Passes | Make multiple passes over the surface. | Ensure a uniform and smooth finish. |

| Consistent Pressure | Apply consistent pressure. | Avoid creating uneven spots. |

The final step is to buff the surface to a high shine.

Buffing Wheel: Use a soft buffing wheel made of cloth or felt.

Polishing Compound: Apply a fine polishing compound to the wheel.

High Speed: Buff the surface at high speed to create a mirror finish.

After polishing, it’s important to clean and inspect the surface.

Remove Residue: Remove any remaining polishing compound with a clean cloth.

Inspect for Defects: Check for any scratches, swirl marks, or other imperfections.

Repeat if Necessary: If any defects are found, repeat the polishing process.

In my factory, we have a dedicated team that specializes in each step of the mirror polishing process. This ensures that each part receives the attention it needs to achieve the highest possible level of reflectivity.

Where do you typically see mirror polish aluminum used? Let’s explore some popular applications.

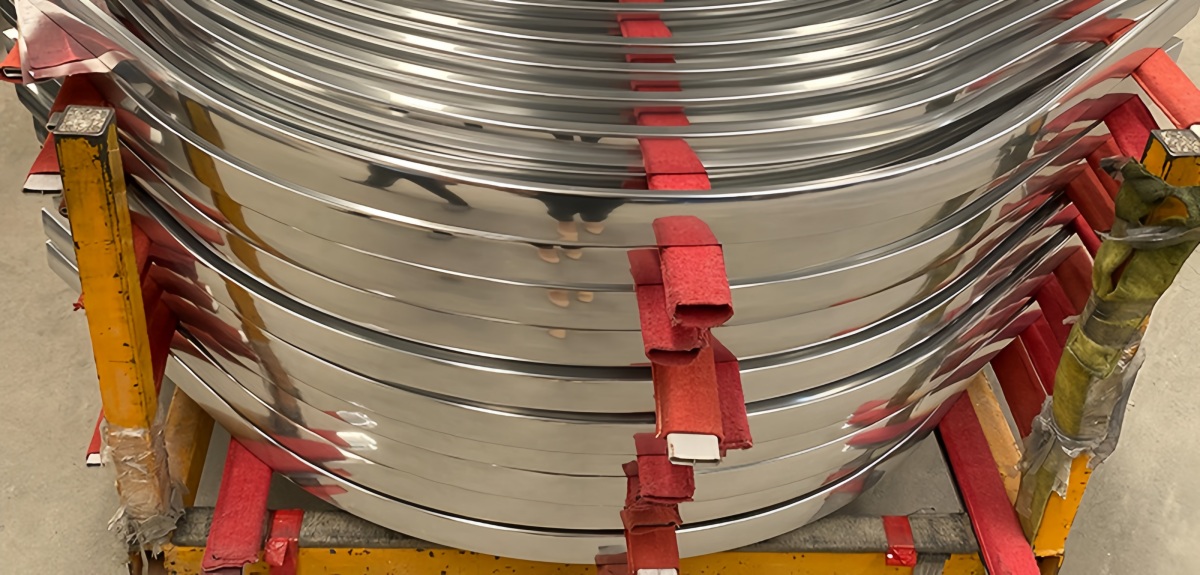

I think it’s often used in decorative trims, reflectors, and high-end appliances. The shiny surface adds a touch of elegance. I’ve also seen it used in scientific instruments where reflectivity is important. It’s a versatile finish for various purposes.

Let’s examine the common applications of mirror polish aluminum in more detail. Its unique properties make it suitable for a variety of uses.

The highly reflective surface makes it ideal for decorative trims.

Aesthetic Appeal: Adds a touch of elegance and sophistication.

Visual Enhancement: Enhances the look of products and structures.

Versatile Use: Can be used in a variety of applications, from automotive trims to interior design.

The reflective properties make it perfect for reflectors.

| Application | Description | Benefit |

| Lighting Fixtures | Used in lighting fixtures to reflect light. | Increases the efficiency of the lighting system. |

| Solar Panels | Used in solar panels to reflect sunlight. | Enhances the energy output of the solar panel. |

| Scientific Instruments | Used in scientific instruments to reflect light or other electromagnetic radiation. | Improves the accuracy and sensitivity of the instrument. |

The sleek, modern look of mirror polish aluminum is popular in high-end appliances.

Premium Look: Gives appliances a high-end, premium appearance.

Consumer Appeal: Attracts customers who value aesthetics.

Easy to Clean: The smooth surface is easy to clean and maintain.

There are many other applications for mirror polish aluminum.

Medical Equipment: Used in medical equipment where a reflective surface is needed.

Aerospace Components: Used in aerospace components where lightweight and high reflectivity are important.

In my factory, we’ve produced mirror polish aluminum parts for a wide range of applications. The versatility of this finish makes it a popular choice for many different industries.

Mirror polish aluminum offers a shiny and durable surface. The process makes it a great option.