Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

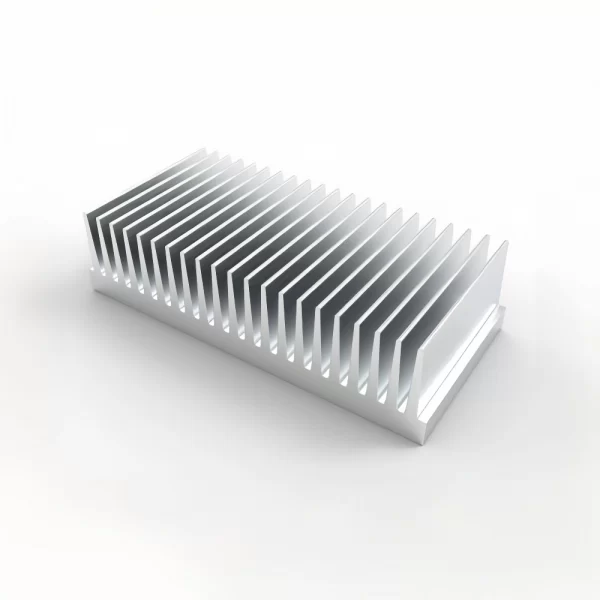

Extruded Aluminum Heatsink offers efficient cooling for electronic devices. This article explores the advantages of using extruded aluminum, including its excellent thermal conductivity and design flexibility. Learn how to select the right heatsink based on thermal requirements, space constraints, and airflow conditions. Discover why extruded aluminum is a cost-effective and lightweight solution for heat management. Maximize the performance and lifespan of your electronics with the right extruded aluminum heatsink!

We make a lot of heatsinks. Extruded aluminum is one of our favorite materials. Let’s see why!

Extruded aluminum heatsinks are devices used to take heat away from electronic parts. They are made using a process called extrusion, which shapes the aluminum into a specific design. In my factory, we use extruded aluminum because it’s good at spreading heat and is easy to make into different shapes.

So, what makes extruded aluminum heatsinks so good? Let’s find out.

Why do we like using extruded aluminum for heatsinks? I’ll tell you the main benefits.

I think the best thing about it is that it’s great at moving heat away. Also, we can make it into almost any shape we need, which is very helpful. Extrusion is also a cost-effective way to make heatsinks, especially when we need them in large numbers.

Let’s dive deeper into the advantages of using extruded aluminum for heatsinks. These benefits make it a popular choice in many electronic applications.

Aluminum is a good conductor of heat.

Efficient Heat Transfer: It can quickly move heat away from the electronic component.

Lower Operating Temperatures: This helps keep the component running at a safe temperature.

Improved Performance: Lower temperatures can improve the performance and lifespan of electronic devices.

Extrusion allows for complex and customized designs.

| Feature | Description | Benefit |

| Fin Shape | Fins can be designed in various shapes, such as straight, curved, or pin fins. | Increases the surface area for heat dissipation. |

| Fin Spacing | The spacing between fins can be adjusted to optimize airflow. | Maximizes heat transfer efficiency. |

| Mounting Features | Mounting features can be integrated into the heatsink design. | Simplifies the assembly process. |

Extrusion is a cost-effective manufacturing process.

High Volume Production: It’s well-suited for high-volume production.

Low Material Waste: It generates minimal material waste.

Reduced Machining: It requires less machining compared to other manufacturing methods.

Aluminum is a lightweight material.

Reduced Weight: It doesn’t add a lot of extra weight to the device.

Easier Handling: It’s easy to handle and install.

Improved Portability: It can improve the portability of electronic devices.

In my factory, we’ve seen how these advantages make extruded aluminum heatsinks a smart choice for many different applications.

What should you think about when choosing a heatsink? I’ll give you some pointers.

I think you need to consider how much heat needs to be moved, how much space you have, and what the airflow is like. Also, you need to make sure it’s easy to install. The right heatsink will keep your device running cool and reliably.

Let’s dive deeper into how to select the right extruded aluminum heatsink. Choosing the right heatsink is crucial for ensuring the proper cooling of electronic components.

Determine the amount of heat that needs to be dissipated.

| Parameter | Description | Impact |

| Power Dissipation | The amount of power dissipated by the electronic component, measured in watts. | Determines the required heatsink size and thermal resistance. |

| Ambient Temperature | The temperature of the surrounding environment. | Affects the heat transfer efficiency of the heatsink. |

| Maximum Component Temperature | The maximum allowable temperature of the electronic component. | Ensures that the component operates within its safe temperature range. |

Consider the available space for the heatsink.

Size Limitations: The size of the heatsink may be limited by the available space in the device.

Height Restrictions: Height restrictions may limit the fin height.

Evaluate the airflow conditions in the device.

Natural Convection: Relies on natural airflow to dissipate heat.

Forced Convection: Uses a fan or blower to increase airflow.

Choose a heatsink that is easy to mount.

Clip Mounts: Simple and easy to install.

Screw Mounts: Provide a secure and reliable attachment.

Adhesive Mounts: Convenient for applications where screws or clips cannot be used.

In my factory, we help our clients select the right extruded aluminum heatsink for their specific needs. We consider all of these factors to ensure that the heatsink provides adequate cooling and is easy to install.

Extruded aluminum heatsinks are good at moving heat. By choosing the right one, you can keep electronics cool.