Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

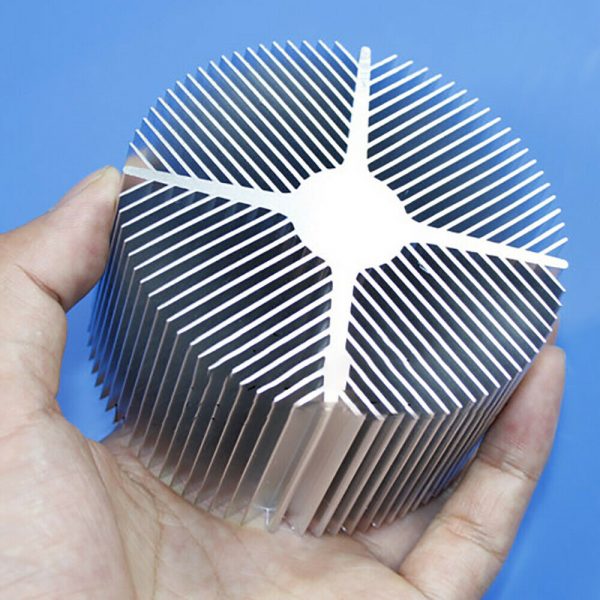

Aluminum heat sinks are crucial for keeping electronics cool and preventing overheating. This guide explores their purpose, functionality, and different types, helping you choose the best option. Learn how these essential components dissipate heat through conduction, convection, and radiation. Discover the advantages of extruded, stamped, and bonded fin heat sinks. Understand how to select the right heat sink by considering heat load, size, and airflow. Ensure optimal performance and longevity for your electronic devices.

Are electronics getting too hot? Worried about damage? Let’s explore aluminum heat sinks and how they can help.

From my experience at ALUT, aluminum heat sinks are used to move heat away. They stop electronics from overheating. This keeps things running smoothly.

So, what makes them so good? Keep reading to learn more.

Why use an aluminum heat sink at all? What problems do they solve for us?

I can say that aluminum heat sinks are important because they keep electronics cool. This helps them last longer. They also prevent damage from too much heat.

The main job of an aluminum heat sink is to take away heat from electronic parts. These parts, like CPUs and GPUs, make heat when they work. If this heat is not controlled, it can cause problems:

Slower performance: High heat can make parts slow down.

Shorter life: Too much heat can damage parts over time.

System problems: Overheating can cause crashes and errors.

Permanent damage: In some cases, overheating can break parts completely.

Aluminum heat sinks fix these problems by giving the heat a way to move away from the part. Aluminum is good for this because it moves heat well, is light, and doesn’t cost too much.

Here is a simple table showing the benefits:

| Benefit | Explanation |

| Cools things | Moves heat away, stopping overheating. |

| Better work | Keeps parts working as they should. |

| Longer life | Helps electronics last longer. |

| Fewer problems | Stops crashes and errors from overheating. |

There are different kinds of aluminum heat sinks for different jobs. Some common types are:

Extruded: Made by pushing aluminum through a mold. Cheap for making a lot.

Stamped: Made by stamping aluminum sheets. Good for low-power uses.

Bonded Fin: Has fins stuck to a base. Offers a lot of surface area for cooling.

Choosing the right type depends on how much heat there is, how much space you have, and how much money you want to spend.

At ALUT, quality control is a key need for our customers, so we implement strict inspections for every order that goes through our factory. This includes random inspections and full inspections based on a customer’s acceptable quality limit (AQL). This makes sure our products’ dimensions and specifications meet design requirements, greatly reducing the possibility of customer complaints.

Okay, so they cool things. But how exactly do they do that?

Aluminum heat sinks work by taking heat away from parts. They then let the heat go into the air. This keeps the parts at a safe temperature, which I’ve seen firsthand at ALUT.

The way an aluminum heat sink works uses simple ideas about heat moving: conduction, convection, and radiation.

Conduction:

This is when heat moves through something by touching it.

When a part makes heat, it touches the heat sink, and the heat moves to the heat sink.

Aluminum is used because it’s good at moving heat quickly.

Convection:

This is when heat moves through air or liquid.

The heat sink has fins that touch the air. The heat moves from the heat sink to the air.

When the air gets hot, it goes up, and cooler air comes in. This helps move the heat away.

Using a fan makes this work even better.

Radiation:

This is when heat moves through the air without touching anything.

The heat sink sends heat into the air.

More Surface:

The greater the surface area of the aluminum heat sink, the more heat it can transfer to the surrounding environment.

Material:

The type of material used in the aluminum heat sink can also affect its efficiency.

Airflow:

Providing adequate airflow over the heat sink helps to remove the heated air and replace it with cooler air.

Here’s a table summarizing the heat transfer methods:

| Heat Transfer Method | Description | How It Works in a Heat Sink |

| Conduction | Heat transfer through direct touch | Heat goes from the part to the aluminum heat sink. |

| Convection | Heat transfer through moving air | Heat goes from the heat sink’s surface to the air, which then goes up and away. |

| Radiation | Heat transfer through the air | Heat goes right from the heat sink into the air. |

Without the heat sink, the CPU would quickly overheat and could be damaged. To help with this, we provide process control services that make sure the aluminum products we make are stable and have the right thermal characteristics to ensure maximum customer benefit.

So, are all aluminum heat sinks the same? Are there different types to choose from?

I’ve seen many kinds of aluminum heat sinks at ALUT. There are extruded, stamped, and bonded fin types. Each one works best for different uses.

Aluminum heat sinks come in many designs. Each one is good for different things, based on how much cooling is needed, how much space there is, and how much money you want to spend. Knowing about these types can help you pick the right one.

Extruded Heat Sinks:

*Made by pushing aluminum through a mold.

*Have fins running along the heat sink.

*Good for making a lot of them cheaply.

Stamped Heat Sinks:

*Made by stamping aluminum sheets.

*Have simple designs.

*Cheap for making a lot.

Bonded Fin Heat Sinks:

*Have fins stuck to a base.

*Have a lot of surface area for cooling.

*Cool well.

Here’s a quick comparison table:

| Type | How It’s Made | Good For | Not Good For |

| Extruded | Pushing through a mold | Making a lot cheaply | Complex designs |

| Stamped | Stamping aluminum | Low-power uses | High heat |

| Bonded Fin | Sticking fins to a base | Cooling well | Cost more |

For example, we can supply our customers with standard products or customize them per the drawings they give us. Because of our integrated logistics solutions, we have confidence that we can quickly deliver these customized products to our customers, greatly reducing the customer’s risk of delayed production caused by late delivery.

Alright, there are many choices. How do you pick the right one for your needs?

Choosing the right one means thinking about things like how much heat there is, how big it is, and how much air is flowing. More heat needs a bigger heat sink. I consider these things often.

Choosing the correct aluminum heat sink involves a step-by-step guide:

Figure out the Heat:

Figure out how much heat the electronic part will make.

Think about Air:

The temperature of the air around the device affects the cooling.

Calculate the Resistance:

Figure out how well the heat sink needs to move heat.

Pick the Right Type:

Based on the heat. Choose the right type of aluminum heat sink.

Check the Size:

Make sure the heat sink fits in the space you have.

We provide supplier procurement services for our customers, with a high degree of custom engineering capability. This, coupled with our quality control practices, ensures our customers are equipped to choose and receive the best quality heat sink for their needs.

Aluminum heat sinks keep electronics cool and working well.