住所

304ノース・カーディナル

セント・ドーチェスター・センター(マサチューセッツ州02124

勤務時間

月曜日~金曜日:午前7時~午後7時

週末午前10時~午後5時

Struggling to find aluminum parts that fit your exact project needs? Standard profiles often mean making compromises in design or function. From my experience, I believe custom aluminum extrusion profiles offer the perfect, tailored solution.

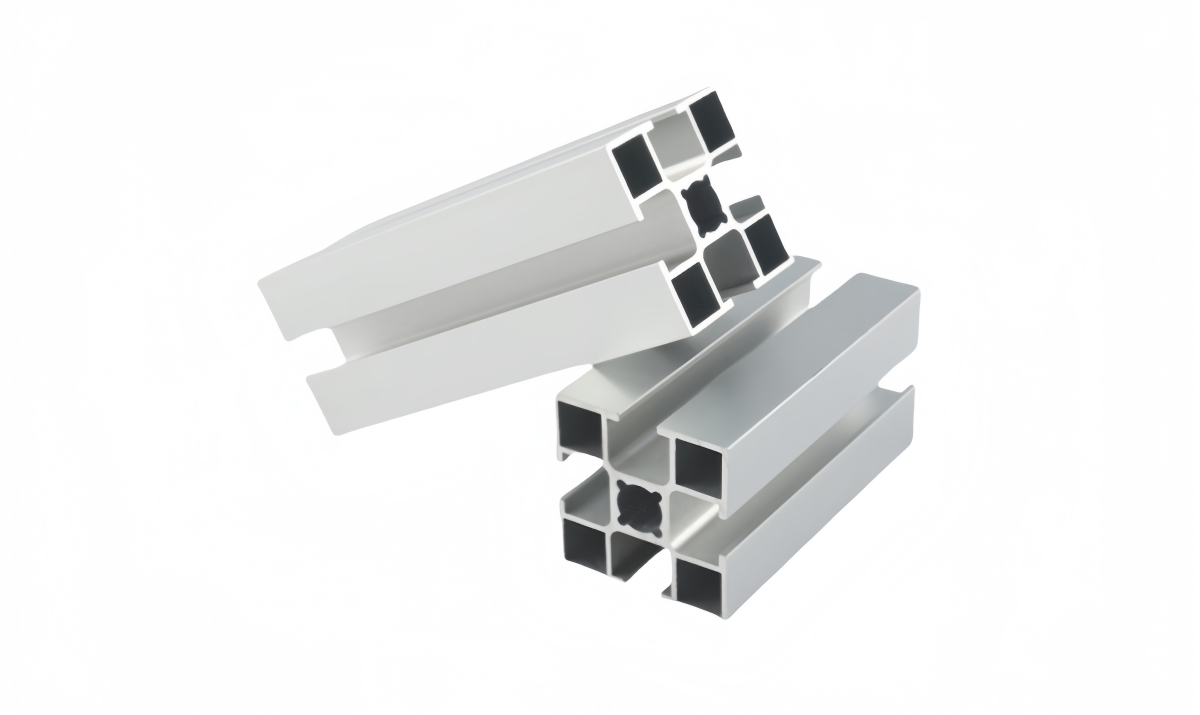

Based on my work here at ALUT, I define custom aluminum extrusion profiles as unique aluminum shapes created specifically for one application. We achieve this by heating a solid aluminum cylinder (a billet) and forcing it through a specially designed steel die, resulting in a precise cross-section tailored just for your product.

But what does choosing custom really mean for your manufacturing process and final product? It’s about more than just getting a unique shape; it’s about optimizing performance, assembly, and sometimes even cost. Let’s dive deeper into what these profiles are and how they can benefit your business.

Is the term ‘custom aluminum extrusion profile’ a bit fuzzy? You might be missing out on significant design and manufacturing advantages if it is. Let me clarify exactly what we’re talking about here.

From my perspective as a manufacturer, I see custom aluminum extrusion profiles as metal shapes made by pushing heated aluminum through a unique, customer-specific die. Unlike standard, off-the-shelf options that use common dies, we design these profiles precisely for one specific purpose, ensuring a perfect fit and function for your project.

Think of it like getting a tailored suit versus buying one off the rack. The off-the-rack suit might fit okay, but the tailored suit is made precisely for your measurements and preferences. Custom extrusions work the same way for your products. Standard profiles (like simple angles, channels, or tubes) are readily available because they are made using common dies that serve many general purposes. They are often cheaper upfront and available faster for simple needs.

However, when your product requires a specific feature, a non-standard shape, or a particular performance characteristic, a standard profile likely won’t work or will require extra machining and assembly steps. This is where custom profiles shine. We create a die only for your part. This allows for complex shapes, integrated features (like screw bosses, snap-fits, or heat sink fins), and optimization for weight, strength, and assembly.

Aluminum itself brings many benefits to these profiles, whether custom or standard:

Here’s a simple comparison to highlight the differences:

| 特徴 | Standard Aluminum Profiles | Custom Aluminum Extrusion Profiles |

| Die Origin | Common, shared die designs | Unique die designed for one specific part |

| Shape | Simple, common shapes (angles, tubes etc.) | Simple to highly complex, unique shapes |

| Availability | Often stocked, readily available | Made to order |

| Upfront Cost | Lower (no specific tooling cost) | Higher (requires investment in a custom die) |

| Design Fit | General purpose, may need modification | Precise fit for the intended application |

| Integration | Limited feature integration | Can integrate multiple features, reduce parts |

| Best For | Simple structures, general applications | Specific functions, optimized designs |

Choosing custom means investing in a tool (the die), but the long-term benefits in terms of performance, reduced assembly labor, and potentially fewer overall parts often outweigh this initial cost for businesses needing specialized components. It gives you, the buyer, control over the exact form and function.

Wondering how these intricate metal shapes actually come into being? The manufacturing process might seem complex from the outside. Having overseen countless production runs at our facility, I can walk you through the key steps involved in a clear way.

Based on our factory operations here at ALUT, creating custom aluminum extrusion profiles involves several well-defined stages. We start with a solid aluminum cylinder called a billet, heat it significantly, push it with immense pressure using a ram through a custom-made steel die, carefully cool the resulting shape, and then apply necessary finishing and aging treatments.

The magic really happens inside the extrusion press, but the entire process requires careful control from start to finish to ensure quality and precision, which I know is critical for buyers like you. Let’s break down the typical journey of a custom profile:

Everything starts with the die. Based on your drawings or specifications, engineers design a specialized steel tool (the die) with an opening precisely matching the desired cross-section of your profile. Creating this die is a critical step requiring expertise and precision engineering. This is usually the main upfront investment for custom profiles.

We select the appropriate aluminum alloy based on your requirements (e.g., strength, finish, machinability). We use solid cylindrical logs of this alloy, called billets. These are often cut from longer logs to a length suitable for the extrusion press.

The aluminum billet and the extrusion die are both heated. The billet is heated typically to between 800°F and 925°F (425°C to 500°C), depending on the alloy. This makes the aluminum malleable but not molten. The die is also heated to ensure smooth metal flow and prevent thermal shock.

The heated billet is loaded into the extrusion press container. A powerful hydraulic ram applies immense pressure (from hundreds to thousands of tons) to the back of the billet. This forces the softened aluminum through the opening(s) in the heated die. The aluminum emerges on the other side as a continuous profile with the exact cross-section of the die opening.

As the profile exits the die, it’s guided along a run-out table. It needs to be cooled carefully to achieve the desired metallurgical properties. This might involve air cooling or passing through a water bath (quenching). The cooling rate is critical for the final temper and strength.

After cooling, the long extrusion often has some slight twisting or bowing. It’s moved to a stretcher, gripped at both ends, and pulled slightly to straighten it and relieve internal stresses.

The straightened extrusion, which can be very long (sometimes over 100 feet), is then cut to the specified lengths required for your order, typically using a high-speed saw.

For many alloys (like the common 6061 or 6063), the extrusions undergo an aging process to achieve their final strength and hardness (temper). This involves heating them in a controlled oven for a specific time and temperature (e.g., T5 or T6 temper).

Depending on your needs, the profiles might undergo secondary operations like precision cutting, drilling, punching, CNC machining, or surface finishing (like anodizing, powder coating, or painting). Quality control checks happen throughout this process.

Here’s a summary of the core steps:

| Step # | Process Stage | Key Action | 目的 |

| 1 | Die Creation | Design & machine steel die | Define the profile’s cross-sectional shape |

| 2 | Billet Prep | Select alloy, cut billet to size | Prepare raw material for extrusion |

| 3 | Heating | Heat billet & die | Make aluminum malleable, ensure smooth flow |

| 4 | 押出 | Push billet through die with ram | Form the continuous aluminum profile |

| 5 | Cooling / Quenching | Control cooling rate after exiting die | Achieve initial metallurgical properties |

| 6 | Stretching | Pull extrusion to straighten | Correct minor distortions, relieve stress |

| 7 | Cutting | Saw profile into required lengths | Meet customer length specifications |

| 8 | Aging (Heat Treatment) | Controlled heating (for certain alloys) | Achieve final hardness and strength (temper) |

| 9 | Finishing (Optional) | Apply surface treatments or machine features | Meet final appearance & functional requirements |

Understanding this process helps appreciate the precision involved and why factors like die design and quality control are so crucial – things we focus heavily on at ALUT to prevent the very issues (like dimensional problems or delays) that I know cause headaches for purchasing managers.

Thinking standard, off-the-shelf aluminum profiles are always the easier or cheaper route? Sometimes they are, for very simple needs. But choosing standard might severely limit your design possibilities or force you into extra, costly manufacturing and assembly steps down the line. Let me show you why custom extrusion profiles often provide superior value, especially for specialized products.

In my view, gained from helping many clients optimize their parts, choosing custom aluminum extrusion profiles offers major advantages over standard ones. You get complete design freedom for complex shapes, you can select the perfect alloy for the job, integrate multiple functions directly into the single profile, and often achieve a much more efficient and cost-effective final product assembly.

While standard profiles have their place, relying on them exclusively can be like trying to build a complex machine using only basic Lego bricks. You might make it work, but it won’t be elegant, efficient, or optimized. Custom extrusions give you the specialized pieces you need from the start. Let’s look closer at the compelling reasons to go custom:

This is the most obvious benefit. Custom extrusions free you from the constraints of standard shapes. Need an integrated hinge, a channel for a gasket, a heat sink feature, a snap-fit mechanism, or a unique aesthetic curve? We can design the die to create that exact profile shape. This allows for innovative product designs that simply aren’t possible with standard components. Your engineers can design the part they need, not just the part that’s readily available.

While standard profiles are typically available in only a few common alloys (like 6063 or 6061), custom extrusion allows you to specify the exact aluminum alloy that best suits your application’s requirements. Need higher strength? Better corrosion resistance? Enhanced machinability? Superior surface finish capabilities? We can select from a wider range of alloys (like the 2xxx, 5xxx, or 7xxx series) and tempers (like T4, T6, T52) to precisely match the mechanical and environmental demands of your product.

This is a huge factor for efficiency. A single custom extrusion can often incorporate features that would otherwise require multiple standard parts and subsequent assembly operations. For example, you could integrate:

By integrating these features directly into the profile, you reduce the number of individual parts you need to source, stock, and assemble.

Following directly from feature integration, using custom profiles often dramatically cuts down on assembly time and labor costs. Fewer parts mean fewer connections, less fastening hardware (screws, rivets, welds), and simpler assembly jigs. This speeds up your production line and reduces opportunities for assembly errors – addressing a key pain point around production delays.

Because the profile is designed specifically for its purpose using the optimal alloy and shape, the final product often performs better. It might be stronger, lighter, more rigid, dissipate heat more effectively, or simply fit together more precisely. This contributes to higher overall product quality and reliability, minimizing issues related to poor fit or function which I know can lead to costly rejects or field failures.

Yes, there is an upfront cost for designing and manufacturing the custom extrusion die. This tooling investment can range from a few thousand dollars upwards, depending on complexity. However, for medium to high volume production runs, the savings from reduced material waste (you’re only getting the shape you need), lower assembly costs, and fewer individual components often quickly offset this initial tooling expense. It’s crucial to analyze the total cost of ownership, not just the price per foot of the raw profile.

Here’s a table summarizing the trade-offs:

| Aspect | Standard Profiles | カスタムプロファイル |

| Design Freedom | Very Limited | Virtually Unlimited |

| Alloy Choice | Limited (typically 6063, 6061) | Wide Range (optimized for application) |

| Feature Int. | Low (requires secondary ops) | High (can integrate many features) |

| Assembly | Can be complex, more parts & labor | Simpler, fewer parts, faster assembly |

| Performance | May be compromised / over-engineered | Optimized for specific requirements |

| 金型費用 | None / Low | Moderate to High (one-time investment) |

| Piece Price | Generally Lower | Can be higher (but total cost often lower) |

| Lead Time (Initial) | Shorter | Longer (due to die creation) |

| Suitability | Simple structures, low volume, prototyping | Complex parts, optimized designs, medium-high vol |

Ultimately, the decision depends on your specific project needs. But for purchasing managers looking for quality, efficiency, and ways to avoid downstream production problems, custom aluminum extrusion profiles offer compelling advantages that standard parts simply cannot match.

Are you limiting your product designs based on a misconception of what’s possible with custom aluminum extrusion profiles? Many engineers and buyers initially think that only simple shapes like angles, tubes, or channels can be extruded. As someone who works with this process daily, I’m here to tell you the possibilities are incredibly vast and often surprising.

From years of manufacturing diverse components at ALUT, I know custom aluminum extrusion profiles can achieve an incredible variety of shapes, far beyond basic geometry. We can produce everything from simple solid bars and angles to extremely complex, multi-hollow profiles with intricate internal details, all tailored precisely to meet specific functional and aesthetic requirements.

The extrusion process is remarkably versatile. Essentially, if you can design a continuous cross-section, there’s a very high probability we can extrude it in aluminum. The limiting factors are more about die design complexity, material flow dynamics, and cost-effectiveness rather than an inherent inability to form shapes. Let’s explore the kinds of shapes commonly produced:

These are the simplest types, with no enclosed voids or openings. Think of solid bars, rods, angles (L-shapes), channels (U-shapes), T-shapes, Z-shapes, and flat strips. Even within “solid,” custom profiles can have complex external features like ribs, grooves, or asymmetrical forms.

These profiles feature one or more enclosed voids. Common examples include square, rectangular, and round tubes. However, custom hollow profiles can have very complex internal and external shapes. Think of multi-chambered profiles used in window frames or intricate conduits for wiring or fluids. Creating hollow shapes requires more complex dies (using mandrels supported by bridges within the die).

These are profiles with a partially enclosed void, where the opening or gap is relatively narrow compared to the area of the void itself. They represent a middle ground in complexity between solid and hollow shapes. Designing dies for these requires careful consideration of metal flow through the narrow gap (the “tongue”).

While many shapes are possible, certain features increase the difficulty and cost of extrusion and die manufacturing:

This is where collaboration between your design team and an experienced extrusion supplier like us becomes crucial. By reviewing designs early, we can often suggest minor modifications – slightly increasing a radius, adjusting a wall thickness, or simplifying a complex feature – that can significantly improve manufacturability, reduce costs, and ensure better quality without compromising the part’s core function. This proactive approach helps avoid the pain points of receiving parts that don’t meet spec.

From intricate heat sinks with complex fin arrays to architectural elements with unique aesthetic details, and structural frames with integrated mounting points, the range of shapes achievable through custom aluminum extrusion profiles is truly extensive. Don’t let assumptions about limitations restrict your design vision.

In summary, custom aluminum extrusion profiles offer tailored solutions providing unmatched design freedom and functional integration for countless applications. They empower you to move beyond standard limitations, optimizing performance and often streamlining assembly processes effectively.