住所

304ノース・カーディナル

セント・ドーチェスター・センター(マサチューセッツ州02124

勤務時間

月曜日~金曜日:午前7時~午後7時

週末午前10時~午後5時

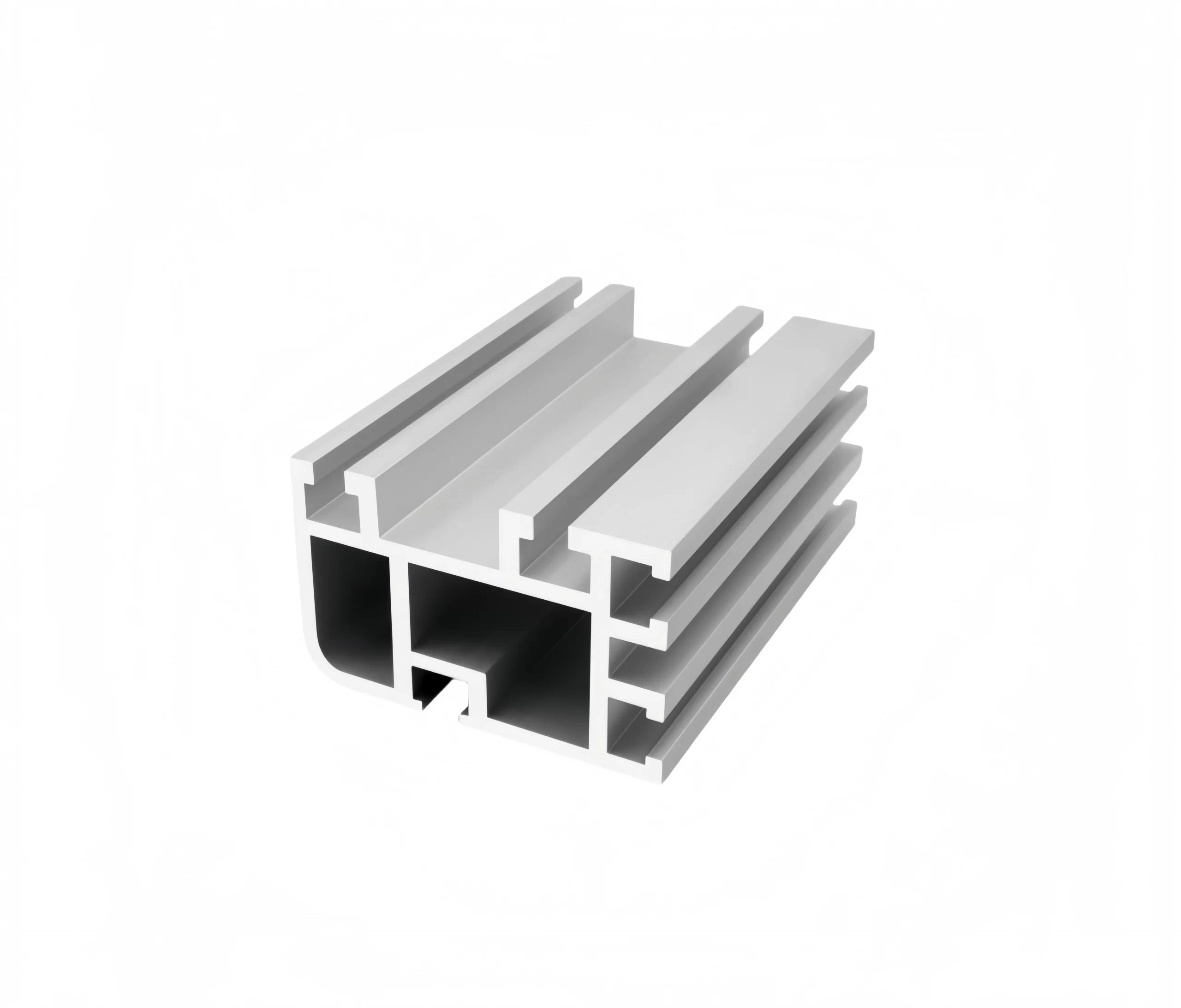

Need parts quickly for your project? Custom extrusions can mean long lead times and high tooling costs. I know standard aluminum extrusion profiles might offer a faster, more economical path.

Based on my manufacturing experience here at ALUT, standard aluminum extrusion profiles are common, pre-designed shapes like angles, tubes, or channels. We produce these using widely available, non-proprietary dies, making them readily accessible and generally more cost-effective for many general-purpose applications compared to fully custom parts.

But are these common profiles always the right fit for every need? Understanding exactly what defines them, the typical materials used, the expected tolerances, and their most common applications is key to making an informed decision. Let’s examine the details.

Confused by the terms “standard” versus “custom” aluminum profiles? Choosing incorrectly can waste valuable time and money if a readily available standard part could have done the job. Let me clarify the distinction based on my experience.

From my perspective manufacturing both types at ALUT, standard aluminum extrusion profiles are fundamentally shapes produced using existing, common dies owned either by extrusion companies like ours or by industry suppliers. Think of common angles, channels (U and C shapes), T-sections, round tubes, square tubes – these are readily available shapes not unique to one specific customer’s design.

The term “standard” primarily refers to the design origin and availability of the die used to create the profile, rather than indicating lower quality. These dies have been designed to produce shapes that serve a wide range of common structural and architectural purposes. Because the design and tooling costs are already absorbed and spread across many users, these profiles offer significant advantages in terms of cost and availability for suitable applications.

| 特徴 | Standard Aluminum Extrusion Profiles | Custom Aluminum Profiles |

| Die Origin | Existing, common industry die | New die created for a specific customer design |

| Shape | Common geometric shapes | Any shape designed by the customer |

| 金型費用 | None for the customer | Significant upfront cost for the die |

| Availability | Often stocked or faster production | Made to order, includes die creation time |

| Design Fit | General purpose, may need adaption | Precise fit for a specific application |

Choosing standard profiles is ideal when your project can utilize these common shapes effectively, prioritizing speed and lower initial cost. However, if your design demands a unique shape or integrated features not found in standard offerings, then custom extrusion becomes necessary.

Does choosing “standard” mean you’re limited to basic or weak alloys? Material choice is critical for performance, and I know buyers worry about this. Let me explain the typical materials used for these common profiles.

In my experience manufacturing countless tons of profiles at ALUT, standard aluminum extrusion profiles are most commonly made from versatile 6000 series alloys, primarily 6063 and 6061. We typically use 6063 for its excellent extrudability and superior surface finish (ideal for architectural applications), while 6061 is chosen when higher structural strength is required.

While aluminum extrusion can utilize a vast range of alloys, the selection available for standard, readily available profiles is typically more focused. The goal is to offer materials that meet the needs of the broadest range of common applications cost-effectively.

The 6000 series alloys, which use magnesium and silicon as the primary alloying elements, hit a sweet spot for extrusions, offering a great combination of properties:

While alloys like the 5xxx series (marine applications) or 7xxx series (aerospace, high strength) offer specialized properties, they are less common as standard, off-the-shelf profiles because:

Therefore, when sourcing standard aluminum extrusion profiles, you can confidently expect them to be made primarily from 6063 or 6061 alloys, offering a reliable balance of properties suitable for a vast range of common applications.

| 特徴 | 6063 Alloy | 6061 Alloy |

| Primary Use | Architectural, Finishing | Structural, Machining |

| 強さ | 中程度 | Higher |

| Extrudability | 素晴らしい | グッド |

| 表面仕上げ | 素晴らしい | グッド |

| 耐食性。 | 非常に良い | グッド |

| Weldability | グッド | グッド |

| Common Tempers | T5, T52, T6 | T6, T651 |

| Typical Profile | Window frame, Trim, Tube | Structural beam, Frame, Bar |

Understanding these common alloy choices helps ensure you select standard profiles with appropriate properties for your project needs.

Worried about whether standard parts will fit together correctly? Tolerances define the expected level of dimensional accuracy. Let me explain the typical precision you can expect from standard aluminum extrusion profiles.

Based on the industry norms that we adhere to at ALUT, standard aluminum extrusion profiles are manufactured to meet established tolerance ranges. These are published by industry organizations like The Aluminum Association (in North America) or CEN (in Europe) and define acceptable variations in dimensions and geometry for general commercial use.

Tolerances are a critical part of any manufacturing specification. They acknowledge that creating parts with absolutely perfect dimensions is impossible and define an acceptable range of variation. For standard aluminum extrusion profiles, these ranges are designed to ensure functionality and interchangeability for common applications while keeping the manufacturing process cost-effective.

The tolerances for standard aluminum extrusion profiles reflect a balance between achievable precision and manufacturing cost-efficiency:

This means that standard aluminum extrusion profiles are:

When sourcing standard aluminum extrusion profiles, you should expect parts manufactured within these well-defined commercial tolerance ranges, ensuring reliable function for their intended general-purpose roles. If your application demands tighter control, then custom or precision extrusion should be considered.

Wondering if these widely available standard aluminum extrusion profiles fit into your specific industry or project type? Their versatility might surprise you; I’ve seen them successfully utilized in an incredibly broad range of applications across many sectors.

From my experience supplying diverse industries from ALUT, standard aluminum extrusion profiles are extremely versatile and commonly used across the board. We see major applications in building and construction (like window and door frames), industrial framing systems (especially T-slots), furniture manufacturing, architectural railings and trim, basic heat sinks, and countless general fabrication projects.

The popularity and widespread use of standard aluminum extrusion profiles stem from their favorable combination of adequate performance for many tasks, cost-effectiveness, and ready availability. Their common shapes are foundational elements in numerous products and structures. Let’s explore some key application areas:

This sector is a massive user of standard aluminum extrusion profiles:

Due to their accessibility through metal suppliers and hardware stores, standard aluminum extrusion profiles are favorites for hobbyists, inventors, and small fabrication shops for countless custom projects.

| Industry Sector | Common Applications of Standard Aluminum Extrusion Profiles | Key Reasons for Use |

| Building/Construction | Windows, doors, railings, trim, solar frames | Cost, availability, finish (6063) |

| Industrial/Machinery | T-slot framing, machine guards, conveyors, workstations | Modularity, ease of assembly |

| Furniture/Fixtures | Table/chair frames, shelving, display stands | Aesthetics, lightweight |

| Electrical/Electronics | Basic heat sinks, simple enclosures, mounting rails | Functionality, availability |

| General Use | DIY projects, prototyping, small fabrications | Accessibility, ease of use |

The widespread adoption across these fields underscores the fundamental utility and economic advantages offered by standard aluminum extrusion profiles for applications where their common shapes and properties align with the project requirements.

Standard aluminum extrusion profiles, typically 6063/6061 alloys, offer cost-effective, readily available solutions with defined commercial tolerances. They are widely used across construction, industry, furniture, and general fabrication applications.