Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Are your LED strip lights overheating or looking unfinished? Simply sticking bare LED strips can lead to poor performance and a messy look. From my factory experience, I know LED aluminum profiles are the professional solution.

Based on my work producing these components at ALUT, I see LED aluminum profiles primarily improving lighting by acting as crucial heat sinks. They draw heat away from the LED chips, extending their lifespan significantly, while also providing physical protection and diffusing the light for a smoother, more appealing illumination.

These profiles do much more than just hold the LED strips. They transform a basic light source into a finished, durable, and high-performing lighting fixture. Let’s explore how they achieve this and what options you have.

Wondering if those metal channels for LED strips are really necessary? You might think they just add cost or complexity. But as a manufacturer, I see firsthand how skipping them leads to problems buyers like you want to avoid – like premature LED failure or harsh, spotty light.

In my experience helping clients integrate lighting, LED aluminum profiles vastly improve lighting by providing essential heat dissipation to keep LEDs cool, offering physical protection against dust and damage, and using diffusers to soften and spread the light evenly, eliminating hotspots and glare.

Bare LED strips, while versatile, face several challenges when installed directly. LED aluminum profiles, often called channels or extrusions, are designed specifically to overcome these issues. Let’s break down the key improvements they offer:

LEDs generate heat during operation. Excessive heat is the primary enemy of LED lifespan and performance. If not managed, heat buildup can cause:

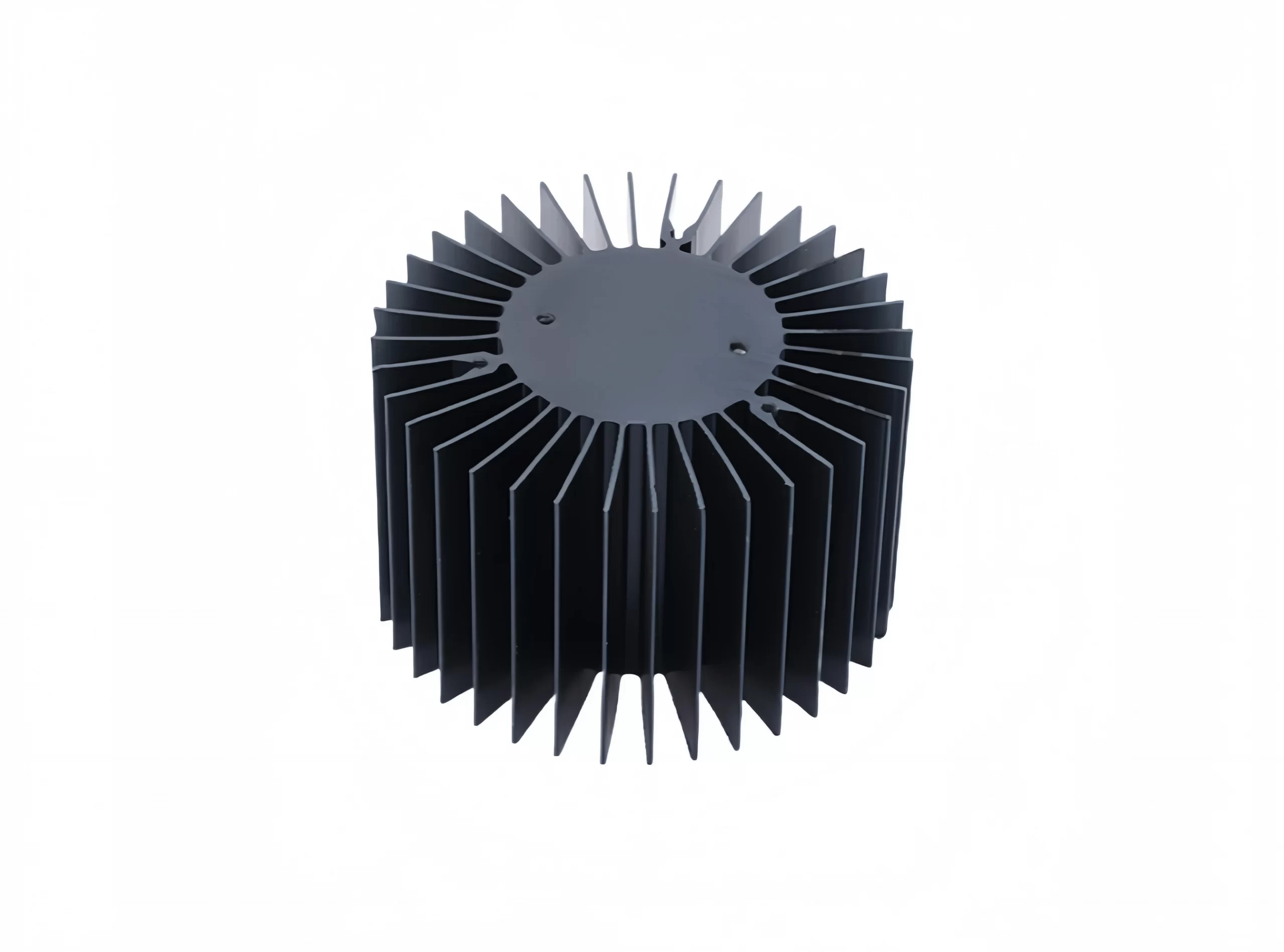

Aluminum is an excellent thermal conductor. The profile acts as a heat sink, drawing heat away from the LED strip and dissipating it into the surrounding air. This passive cooling mechanism is vital, especially for higher-power LED strips. By keeping the LEDs operating within their optimal temperature range, aluminum profiles significantly extend their functional life and maintain consistent light output. For manufacturers integrating LEDs into final products, this improved reliability is critical.

LED strips are relatively delicate. The tiny diodes and circuitry are exposed and vulnerable to:

The aluminum channel provides a sturdy enclosure, shielding the LED strip from these environmental hazards. The diffuser (cover) adds another layer of protection. This ruggedness is essential for ensuring the lighting functions reliably long-term, preventing costly field failures or replacements – a major concern for purchasing managers.

Bare LEDs often produce harsh, distinct points of light (hotspots) and potential glare. This can be visually uncomfortable and unsuitable for many applications. LED aluminum profiles typically come with a diffuser cover (usually made of polycarbonate or PMMA) available in different opacities:

The diffuser spreads the light more evenly, creating a softer, more uniform, and professional-looking illumination. This aesthetic improvement is crucial for architectural lighting, under-cabinet lighting, display cases, and other applications where visual quality matters.

Aluminum profiles provide a clean and stable structure for mounting the LED strips. They often come with mounting clips, brackets, or specific shapes (like corner or recessed profiles) that simplify installation on various surfaces. This ensures a straight, secure fit and a much cleaner final appearance compared to directly adhering LED strips.

Here’s a summary of the benefits:

| Fonctionnalité | Benefit Provided by LED Aluminum Profile | Impact on Lighting System |

| Heatsinking | Efficiently dissipates heat from LED chips | Extends LED lifespan, maintains brightness & color |

| Protection | Shields LED strip from dust, impact, moisture (partially) | Increases durability, reduces failure rates |

| Diffusion | Softens and spreads light evenly via diffuser cover | Eliminates hotspots, reduces glare, improves aesthetics |

| Mounting | Provides a stable and clean mounting structure | Simplifies installation, ensures professional finish |

Investing in the right LED aluminum profile isn’t just an accessory purchase; it’s fundamental to achieving high-quality, long-lasting, and professional LED lighting installations.

Feeling overwhelmed by the variety of LED aluminum profile channels out there? Choosing the wrong type can derail your installation or fail to deliver the desired lighting effect. As someone who manufactures these profiles, let me clarify the main categories you’ll encounter.

From the custom and standard profiles we produce at ALUT, I categorize LED aluminum profiles mainly by their mounting style and shape. Common types include surface-mounted, recessed, corner-mounted, pendant/suspended, and specialized profiles like stair nosing or wardrobe rails, each designed for specific applications and aesthetic outcomes.

The specific type of profile you need depends heavily on where and how you intend to use the LED strip lighting. Understanding the common classifications helps narrow down your choices significantly. Here’s a more detailed look:

Profiles also vary significantly in their physical dimensions:

Here’s a comparison table highlighting key differences:

| Type de profil | Typical Mounting | Common Use Cases | Key Feature | Installation Note |

| Surface Mount | On surface | Under cabinets, ceilings, walls, display cases | Versatile, easy installation | Needs clips or screws |

| Recessed Mount | Into surface groove | Drywall ceilings/walls, furniture, tile installations | Flush, integrated look | Requires precise cutout |

| Corner Mount | In 90° corners | Coves, display cabinets, wall/ceiling junctions | Angled light output (often 45°) | Fits neatly into corners |

| Pendant Mount | Suspended | Overhead general/task lighting, high ceilings | Can be large, sometimes houses drivers | Needs suspension kit |

| Specialty | Application-specific | Stairs, wardrobes, floors | Designed for a specific functional purpose | Varies by specific profile type |

Choosing the right type involves matching the profile’s characteristics to your project’s functional requirements and desired visual outcome. As a supplier, we at ALUT can provide standard types or even develop custom profiles if your project demands unique dimensions or features – a key capability for B2B clients needing specific solutions.

Faced with numerous options, how do you pinpoint the perfect LED aluminum profile for your project? Making the wrong choice can lead to installation headaches, poor lighting quality, or even damage to your LED strips. Drawing on my experience helping clients select components, I can outline a clear selection process.

From my perspective assisting manufacturers and installers, choosing the right LED aluminum profile involves carefully considering several factors: the LED strip’s width and heat output, the desired mounting style (surface, recessed, corner), the required level of light diffusion (clear, frosted, opal cover), IP rating needs, and the overall aesthetic goal.

Selecting the appropriate profile ensures optimal performance, longevity, and visual appeal for your LED lighting installation. It prevents common issues like incompatibility, overheating, or an unsatisfactory lighting effect. Here’s a breakdown of the key factors to evaluate:

Here’s a checklist to guide your selection:

| Consideration | Question to Ask | Importance Factor |

| LED Strip Fit | Does the profile’s internal width match my LED strip? | Critical (Function) |

| Heatsinking | Is the profile rated for my LED strip’s wattage/heat output? | Critical (Lifespan, Quality) |

| Mounting Style | Do I need surface, recessed, corner, or suspended mounting? | Critical (Installation, Aesthetics) |

| Light Effect | Do I need maximum brightness, soft light, or a completely dot-less line? | High (Aesthetics, Visual Comfort) |

| Environment (IP) | Will the installation be exposed to dust, moisture, or water? | High (Durability, Safety – if applicable) |

| Apparence | Does the profile shape and finish match the design? | Medium to High (Aesthetics) |

| Length/Cutting | Are standard lengths suitable, or can it be easily cut? | Medium (Installation) |

By systematically considering these points, you can confidently select the LED aluminum profile that best meets the technical requirements and design vision for your project, ensuring a successful and long-lasting installation.

Thinking LED aluminum profiles are only for basic under-cabinet lighting? While that’s a popular use, their versatility allows for installation in a surprisingly wide range of locations. As a provider of these extrusions, I’ve seen them integrated into countless creative and functional applications.

From my experience supplying various industries, LED aluminum profiles can be installed almost anywhere you need linear lighting. Common applications include architectural coving, under cabinet lighting, stair illumination, retail display cases, furniture integration, wardrobe lighting, ceilings, walls, and even outdoor pathways or building facades when using appropriate IP-rated versions.

The combination of LED technology’s flexibility and the protective, finishing qualities of aluminum profiles opens up vast possibilities for both functional and decorative lighting. Here are some common and innovative places where these profiles shine:

Here’s a table linking profile types to common installation areas:

| Installation Area | Common Profile Types Used | Principales considérations |

| Under Cabinets | Surface Mount (Slim), Corner Mount | Task lighting focus, diffuser choice for glare control |

| Ceiling Coves | Surface Mount, Corner Mount | Indirect ambient lighting, heat dissipation if enclosed |

| Recessed in Drywall | Recessed Mount (with flanges) | Clean integration, precise cutout needed |

| Stair Treads | Stair Nosing Profile | Durability, slip resistance, safety lighting |

| Display Cases | Surface Mount (Mini), Corner Mount | Focused light on objects, profile discreetness |

| Wardrobes | Surface Mount, Wardrobe Rail Profile | Even illumination, optional sensor integration |

| Outdoor Pathways | Floor Profile (IP67+, walk-over rated) | High IP rating, durability, resistance to elements |

| Suspended Lighting | Pendant Profile | Ceiling height, suspension kit, potential driver housing |

The adaptability of LED aluminum profiles makes them a valuable tool for lighting designers, architects, manufacturers, and installers. They provide a framework to deploy LED strip lighting effectively, safely, and aesthetically in nearly any environment imaginable.

In conclusion, LED aluminum profiles are essential components for enhancing LED strip lighting. They provide critical heat sinking, protection, light diffusion, and ensure a professional, finished look for diverse indoor and outdoor applications.