Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

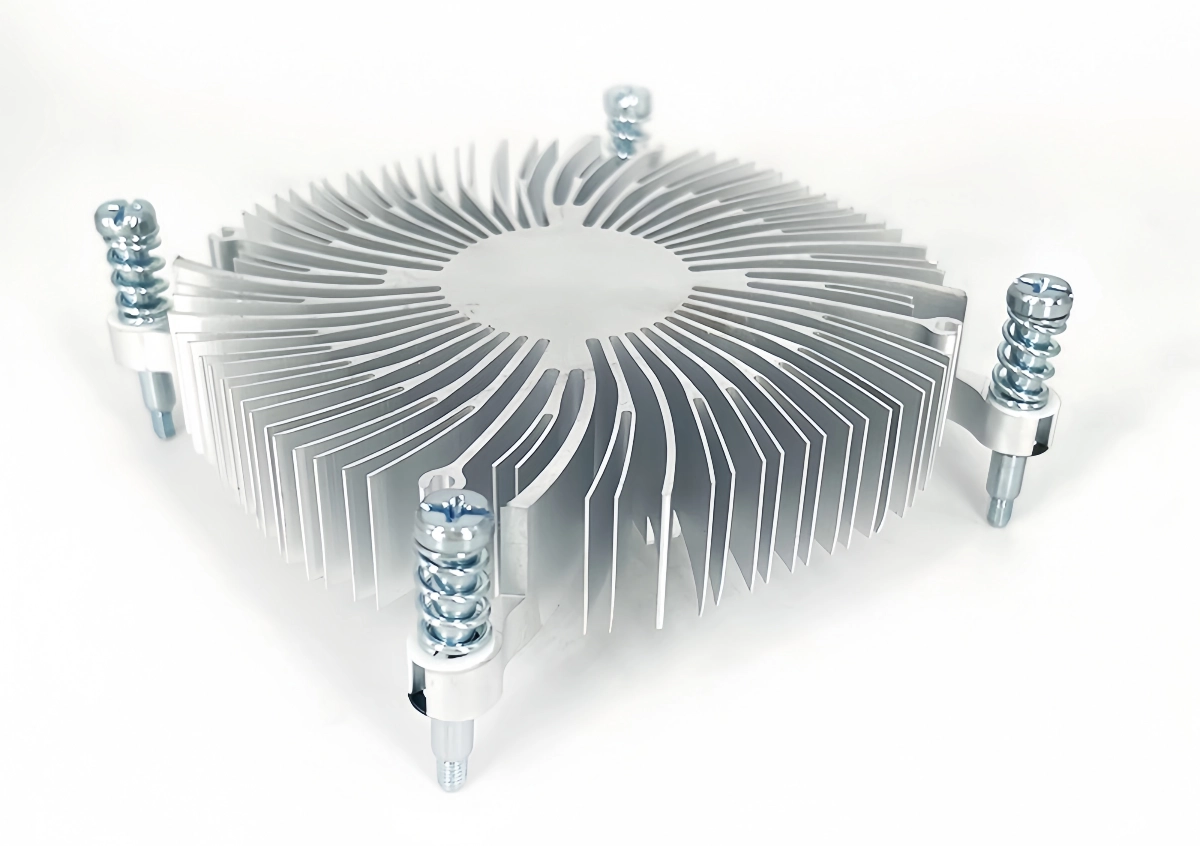

Struggling with electronics getting too hot? I’ve seen firsthand how heat damage can derail a project. Let’s look at how tiny fins make a huge cooling difference.

From my experience, aluminum heat sink fins are critical. They dramatically increase the surface area touching the air. This larger area lets heat escape much faster through convection and radiation, keeping components cool and reliable. It’s a simple concept with a powerful impact.

Understanding how these fins work is just the start. We need to explore the different types, how they’re made, and which manufacturing methods might be best for your specific needs. Let’s dive in.

Ever worry that heat is silently degrading your components? I know the feeling. Limited space often makes cooling a real challenge, but fins are a clever solution.

In my projects, I rely on fins because they maximize the surface area available for heat transfer. More surface means more contact with the surrounding air, allowing heat to dissipate efficiently through natural or forced convection. This prevents dangerous temperature buildups.

Aluminum heat sink fins work based on fundamental heat transfer principles. Electronic components generate heat, and this heat must be removed to prevent damage or performance loss. Heat sinks draw heat away from the component (conduction) and release it into the surrounding air. Fins are the essential part that maximizes this release.

Heat moves mainly in three ways relevant here:

The primary role of fins is to drastically increase the aluminum heat sink’s surface area without making the base much larger. More surface area directly enhances heat transfer to the air, especially via convection. The rate of convective cooling is roughly proportional to the surface area exposed to the air. By adding fins, we significantly increase this area, allowing much more heat to escape.

Effective cooling also depends on airflow between the fins. Air absorbs heat from the fin surfaces. Good design ensures sufficient spacing for air to flow freely, carrying heat away and allowing cooler air to reach the surfaces. If fins are too close, they can choke airflow, reducing efficiency. The balance between surface area (more fins) and airflow (enough space) is crucial for optimal performance.

Choosing the right heat sink isn’t just about size. I’ve learned that using the wrong heat sink fin type can seriously compromise cooling performance, no matter how big the sink is.

Based on my experience sourcing parts, the most common types I encounter are straight fins, pin fins, and flared fins. Straight fins are versatile, pin fins excel with multi-directional airflow, and flared fins offer a good surface area-to-airflow balance.

The design of aluminum heat sink fins significantly impacts performance. Different shapes cater to various cooling needs, airflow conditions, and manufacturing methods. Knowing the common types helps in selecting the best solution.

These are flat fins arranged parallel on the base.

These are cylindrical or square pins projecting from the base.

Straight fins where the tips are spaced further apart than the base.

Here’s a simple comparison:

| Fin Type | Manufacturing Ease | Airflow Suitability | Typical Performance | Cost Factor |

| Straight (Plate) | High (Extrusion) | Unidirectional (Forced) | Bien | Bajo |

| Pin | Low (Forged/Machined) | Omnidirectional/Low Speed | Excellent (esp. low airflow) | Alta |

| Flared | Medio | Low Speed/Natural Conv. | Very Good (low resistance) | Medio |

| Folded/Stamped | Medium (Assembly) | Forced/High Density | Excellent (high surface area) | Medio-Alto |

Selecting the right type involves balancing thermal needs, airflow, space, and budget.

Ever received samples that didn’t quite match the specs? I have, and it often comes down to the manufacturing method used. Understanding how fins are made is key to ensuring quality.

From what I’ve seen in factories, common methods include extrusion for long, straight fins, CNC machining for complex shapes or prototypes, forging for pin fins, and stamping/bonding for high-density folded fins. Each has its strengths affecting cost and precision.

The production method for aluminum heat sink fins impacts their shape, precision, performance, and cost. Key methods include:

Heated aluminum is forced through a shaped die.

Fins are cut from a solid aluminum block using computer-controlled tools.

Aluminum is shaped using compressive force in a die.

Thin sheet metal fins are stamped/folded and attached to a base.

Molten aluminum is injected into a mold.

| Método | Design Complexity | Precisión | Cost (High Vol) | Coste de utillaje | Material Waste | Typical Fin Type |

| Extrusión | Low (Linear) | Bien | Bajo | Medio | Bajo | Straight |

| Mecanizado CNC | Muy alta | Excelente | Alta | None | Alta | Any (Complex) |

| Forja | Media-alta (3D) | Muy buena | Medio-Alto | Alta | Bajo | Pin, Complex Base |

| Stamping/Bonded | High (Density) | Bien | Medio | Medio | Medio | Folded, Thin |

| Fundición a presión | Alta | Fair-Good | Very Low | Muy alta | Bajo | Complex Shapes |

Understanding these helps discussions with manufacturers like ALUT about design and cost.

This is a common question I encounter: when designing an aluminum heatsink, should we use an extrusion or machine the fins from solid? There’s no single “better” answer, it depends entirely on the project’s priorities.

From my perspective as a manufacturer offering both, extruded fins are generally more cost-effective for standard profiles and high volumes. Machined fins offer superior design flexibility for complex shapes, prototypes, or when integrated features are needed, but usually at a higher unit cost.

Comparing extruded aluminum heat sink fins directly to machined fins involves weighing several key factors: cost, design freedom, performance implications, lead times, and suitability for different production scales. Both methods produce effective heat sinks, but they excel in different areas.

Assuming similar overall dimensions and fin geometry (where possible with both methods), the intrinsic thermal performance of an extruded fin versus a machined fin of the same alloy should be virtually identical. Both methods start with solid aluminum and create an integral fin/base structure. The performance differences arise from the design possibilities each method enables:

| Factor | Extruded Fins | Machined Fins | Which is “Better”? Depends On: |

| Unit Cost (High Vol) | Lower | Higher | Production Volume, Budget |

| Unit Cost (Low Vol) | Higher (if custom die needed) | Lower (No Tooling) | Volume, Prototyping Needs |

| Coste de utillaje | Moderate (Custom Die) | None | Budget, Volume, Use of Standard Profile |

| Flexibilidad de diseño | Moderate (2D Profiles) | Very High (3D Shapes) | Required Geometry Complexity |

| Precision/Tolerance | Bien | Excelente | Application’s Tolerance Requirements |

| Lead Time (Initial) | Longer (Die Creation) | Shorter (Programming) | Urgency for First Parts |

| Lead Time (Production) | Faster (per part) | Slower (per part) | Production Scheduling |

| Material Waste | Bajo | Alta | Material Cost Sensitivity, Sustainability Goals |

| Fin Aspect Ratio | Limited by Process | Less Limited | Need for Very Tall/Thin Fins |

Conclusion on “Better”:

Many projects might even start with machined prototypes and transition to extrusion for mass production if the design can be adapted to extrusion constraints. The optimal choice requires evaluating the specific requirements of the application against the strengths and weaknesses of each manufacturing method.

Aluminum heat sink fins are crucial for cooling, drastically increasing surface area for heat dissipation via convection and radiation. Common types include straight, flared, and pin fins, manufactured by methods like extrusion, machining, or forging. Extruded fins offer cost benefits for volume, while machined fins provide greater design freedom.