Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dark anodized aluminum is an electrochemical process that forms a protective oxide layer integrated with the metal. This finish offers superior durability, corrosion resistance, and a deep, aesthetic color suitable for industrial parts.

I have spent many years working in the aluminum industry. I know that the right finish makes all the difference for your brand. Let me show you how this process works.

Finding the right finish is hard when you do not know the process. Poor surface quality can cause massive project failures. I want to explain the magic behind it.

Dark anodized aluminum is produced by submerging aluminum in an acid bath and passing an electric current through it. This grows an oxide layer that is then colored with dyes or metal salts and sealed.

I want to explain this process in a very simple way. We take a raw aluminum part and put it into a big tank. This tank is filled with an acid solution. We then pass an electric current through the liquid. This does not just coat the metal. It actually changes the surface of the aluminum. It grows a layer of aluminum oxide. I often tell my clients to think of this layer like a hard shell that is part of the metal itself. This layer is very porous, which means it has millions of tiny holes that you cannot see with your eyes.

Once we have this porous layer, we need to add the color. For dark anodized aluminum, we use specific dyes or metal salts. We let these colors soak deep into those tiny holes. This is why the color looks so deep and rich. It is not just sitting on the surface like paint. It is inside the metal structure. After we get the right shade of dark gray or black, we must seal it. We put the parts into a hot water bath or a chemical seal. This closes the tiny holes and locks the color inside forever.

In my factory, ALUT, we manage the entire supply chain. We check the temperature of the tanks every hour. If the acid is too hot, the layer will be soft. If the current is too low, the color will be uneven. I know that as a purchasing manager, you hate getting parts that look different from one another. We use strict process control to ensure every batch of dark anodized aluminum matches your drawings perfectly.

| Variable | Effect on Quality | Our Standard at ALUT |

| Acid Temperature | Affects layer hardness | Constant 20°C (±1°) |

| Current Density | Affects thickness | Controlled by digital rectifiers |

| Dye Time | Affects color depth | Timed to the second |

| Sealing Quality | Affects corrosion resistance | Tested with weight loss method |

You worry that the sun will turn your beautiful parts into a faded mess. This leads to customer complaints and returns. I have seen this happen far too often with cheap coatings.

High-quality dark anodized aluminum does not fade easily if processed with inorganic metal salts or electrolytic coloring. These methods lock the color deep inside the oxide layer, providing excellent UV stability for outdoor use.

I get asked about fading almost every week. Many buyers have had bad experiences where a black part turns gray after a few months in the sun. This usually happens because the supplier used cheap organic dyes. Organic dyes are made of carbon molecules. The UV rays from the sun can break these molecules apart. When the molecules break, the color disappears. This is why some consumer goods look terrible after a summer outdoors.

To prevent this, I always suggest using inorganic metal salts or electrolytic coloring for dark anodized aluminum. Instead of using organic ink, we use metals like tin or cobalt. We use electricity to pull these metal particles into the pores of the aluminum. Since these are actual metals, the sun cannot break them down. This process is more expensive and harder to do, but it is the only way to ensure the finish lasts for 20 years. If your products are sold in the United States or Europe, you need this level of quality to protect your reputation.

You must ask your supplier what kind of dye they use. Many factories in Southeast Asia or China might use organic dyes to save money. They hope you will not notice until after the parts are shipped. I take a different approach. I focus on project management and engineering design. We look at where your part will be used. If it is for an outdoor machine, we only use the most stable coloring methods. We want your dark anodized aluminum to stay dark, no matter how much sun it gets.

| Método | Material Used | Expected Life (Outdoor) |

| Organic Dyeing | Carbon-based dyes | 1 to 3 years |

| Inorganic Dyeing | Mineral salts | 10 to 15 years |

| Electrolytic Coloring | Tin or Cobalt salts | 20+ years |

Your parts get scratched during assembly or shipping. This looks unprofessional and wastes your money. I know a way to make your surfaces nearly as hard as diamond.

Dark anodized aluminum is extremely scratch resistant because the finish is part of the metal, not a coating. The aluminum oxide layer has a ceramic-like hardness that withstands heavy handling and industrial wear.

I like to explain the hardness of dark anodized aluminum by comparing it to other materials. Raw aluminum is a very soft metal. You can scratch it with a fingernail. But when we anodize it, we create a layer of aluminum oxide. This is the same material used to make sandpaper and even sapphires. On the Mohs scale of hardness, it is just below diamond. This means that a standard steel tool will often slide right off the surface without leaving a deep mark.

Many purchasing managers ask me if they should use powder coating instead. I always tell them to look at the bond. Powder coating is like a skin of plastic stuck to the metal. If you hit it, it can chip or peel. Dark anodized aluminum cannot chip or peel because it is grown out of the base metal. It is physically impossible for the layer to come off without grinding away the metal itself. This is a huge benefit for mechanical parts that have tight dimensional tolerances. The layer is very thin, usually between 15 and 25 microns, so it does not change the size of your part significantly.

Even though it is very hard, you still need good logistics management. In our 10,000 square meter factory, we pack every piece of dark anodized aluminum with care. We use custom foam or plastic film to prevent parts from rubbing together. I have seen many suppliers do great work on the finish but ruin it with bad packing. Our service team handles the logistics to ensure your parts arrive in perfect condition. We know that a single scratch can make a part useless for your high-end machines.

| Finish Type | Typical Hardness (HV) | Can it Chip? | Best for |

| Raw Aluminum | 20 – 40 | No | Simple spacers |

| Powder Coating | 60 – 100 | Sí | Decorative covers |

| Dark Anodized Aluminum | 300 – 500 | No | Industrial frames |

| Hard Anodized | 500 – 900 | No | Heavy wear parts |

Choosing the wrong material for your industry can be a costly mistake. It leads to part failure and lost trust. I will help you identify the best uses for this finish.

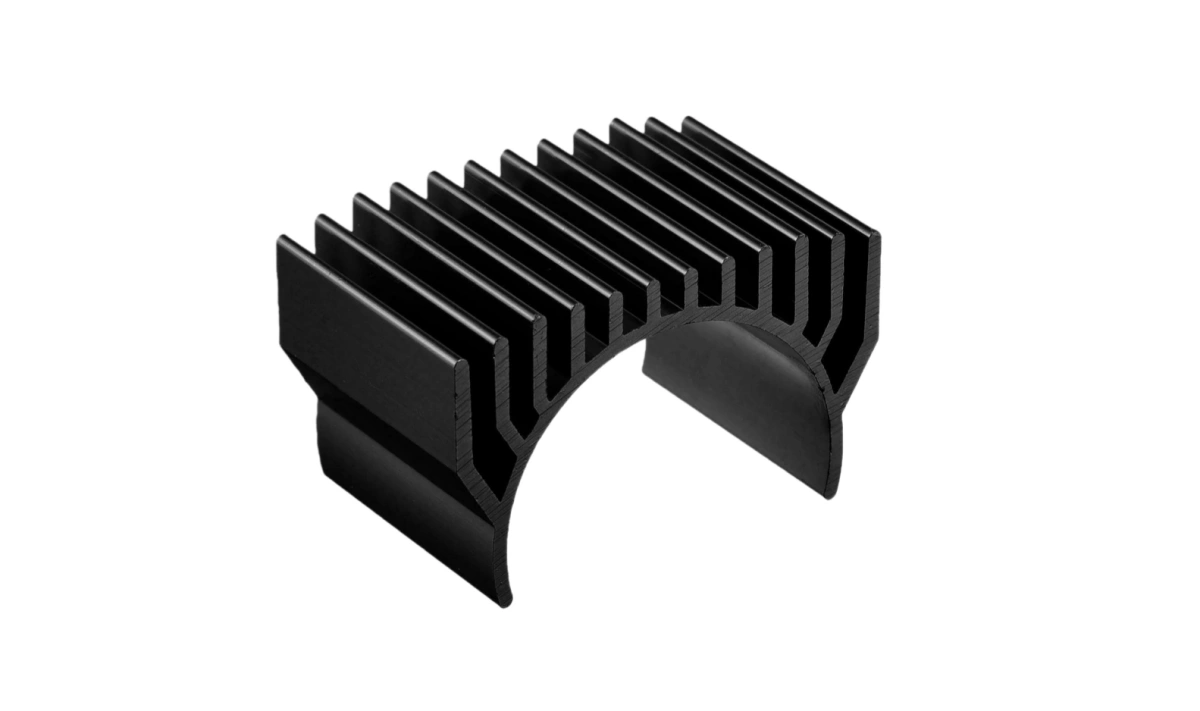

Common applications for dark anodized aluminum include architectural panels, high-end electronics, automotive trim, and precision mechanical parts. Its durability and professional appearance make it the top choice for demanding industrial environments and luxury goods.

I see dark anodized aluminum used in almost every industry today. It has a modern, high-tech look that engineers love. In the world of high-end electronics, companies use it for laptop bodies and camera frames. It feels cold and solid to the touch, which gives the user a feeling of high quality. It also does a great job of hiding fingerprints compared to a shiny, clear finish. This makes the product look clean even after a lot of use.

Another big use for dark anodized aluminum is in thermal management. If you are making LED lights or industrial machines, you need to move heat away from the components. A dark, matte surface is actually better at radiating heat than a shiny one. I have helped many clients in the United States design heat sinks using this finish. It helps the machine run cooler and last longer. We also see it used for high-precision CNC parts in the medical and aerospace fields. These parts need to be tough and look professional.

I work with many buyers who are tired of bad communication and late deliveries. They need a partner who can provide integrated logistics solutions. Whether you need standard products or custom parts based on your drawings, we can handle it. We produce in China to keep costs low, but we follow strict international quality standards. My team provides supplier audits and contract manufacturing so you can focus on selling your products. Using dark anodized aluminum for your parts is a smart move, and we are here to make the process easy for you.

Dark anodized aluminum is the perfect solution for durable, high-quality parts. Contact my team at ALUT to start your project with a reliable partner who understands your needs.