Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

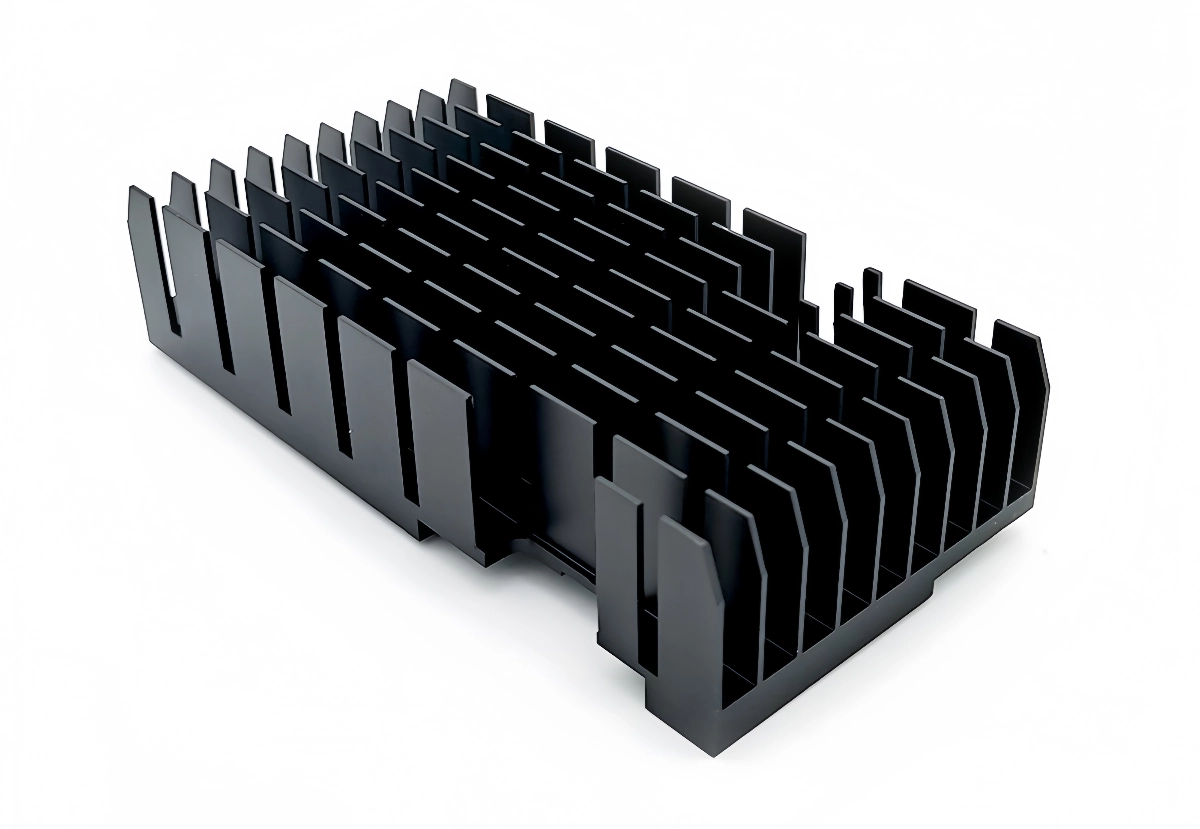

Ever felt the frustration of overheating electronics? I know I have! Let’s explore if custom aluminum heatsinks are the solution.

Custom aluminum heatsinks can be a game-changer! I’ve seen them improve cooling performance, fit specific spaces perfectly, and even reduce noise. For me, the ability to tailor the design to my exact needs makes them a worthwhile investment.

But how do you know if a custom heatsink is right for you? Let’s dive into the benefits, where to find reliable manufacturers and more.

Thinking about going custom? It can seem like a big step. But trust me, the advantages can be significant.

From my experience, the biggest benefit is optimized cooling. I can design a heatsink with the exact fin density and dimensions I need for my components. This means better heat dissipation and a longer lifespan for my electronics.

Custom heatsinks offer a range of benefits that extend beyond simple cooling. The ability to tailor a heatsink to a specific application can lead to improved performance, increased reliability, and even cost savings in the long run.

The primary advantage of custom heatsinks is, of course, superior cooling performance. Standard, off-the-shelf heatsinks are designed to work with a broad range of components and applications. This often means they are not optimized for any specific situation.

With a custom heatsink, you can fine-tune the design to match the exact thermal requirements of your device. This includes adjusting the fin density, fin height, base thickness, and overall dimensions to maximize heat transfer. By optimizing these parameters, you can achieve significantly better cooling compared to a generic heatsink.

Custom heatsinks offer unparalleled design flexibility. You are not limited by the standard shapes and sizes of off-the-shelf products. You can create a heatsink that perfectly fits the available space in your device, even if it is an unconventional shape.

This is particularly useful for compact electronics or devices with complex internal layouts. A custom heatsink can be designed to wrap around other components or fit into tight spaces, maximizing cooling efficiency without compromising the overall design.

While aluminum is a popular choice for heatsinks, custom solutions offer the flexibility to choose different materials or combinations of materials. For example, you could use a copper base for its excellent thermal conductivity and aluminum fins for their light weight.

The choice of material can significantly impact the performance and cost of the heatsink. By carefully considering the thermal properties, weight, and cost of different materials, you can optimize the design for your specific needs.

In some applications, the noise generated by cooling fans can be a concern. Custom heatsinks can be designed to minimize the need for fans, reducing noise levels.

By increasing the surface area of the heatsink and optimizing its design for natural convection, you can often achieve sufficient cooling without relying on noisy fans. This is particularly important for devices used in quiet environments, such as medical equipment or audio recording studios.

Effective cooling is essential for the longevity of electronic components. Overheating can lead to premature failure and reduce the lifespan of your devices.

Custom heatsinks can help to prevent overheating by efficiently dissipating heat away from sensitive components. This can extend the lifespan of your electronics and reduce the risk of costly repairs or replacements.

While custom heatsinks may have a higher initial cost compared to off-the-shelf products, they can lead to cost savings in the long run. By improving the reliability and lifespan of your electronics, you can reduce the need for repairs and replacements.

Additionally, custom heatsinks can optimize the performance of your devices, potentially reducing energy consumption and lowering operating costs.

Here is a table summarizing the benefits of custom heatsinks:

| Benefit | Description |

| Improved Performance | Optimized design for maximum heat transfer. |

| Design Flexibility | Tailored to fit specific spaces and unconventional shapes. |

| Material Options | Choice of different materials to optimize performance and cost. |

| Reduced Noise | Minimized need for fans, reducing noise levels. |

| Longer Lifespan | Effective cooling prevents overheating and extends component lifespan. |

| Cost Savings | Reduced repairs, replacements, and potentially lower energy consumption. |

Finding the right manufacturer can feel overwhelming. Been there, done that! Here’s how I approach it.

I usually start with online research. I look for manufacturers with a strong track record, positive reviews, and experience in producing custom heatsinks. Checking their certifications and quality control processes is also a must for me.

Sourcing a dependable custom heatsink manufacturer is vital for the success of any project that demands tailored thermal solutions. Here’s a breakdown of the strategies and checkpoints I use, coupled with a critical assessment of what to look for.

Trade shows offer a chance to meet potential manufacturers face-to-face. For me, it’s a great way to gauge their expertise and commitment to quality.

Here’s my breakdown of must-haves:

I once worked with a manufacturer who initially seemed promising. Their prices were great, but their communication was terrible, and the first batch of samples was flawed. I learned the hard way that prioritizing communication and quality control from the start is crucial.

Before committing to a manufacturer, consider conducting an audit of their facilities. This can help you verify their capabilities, processes, and quality control measures. You can hire a third-party inspection company to conduct the audit on your behalf.

Clear and open communication is essential for a successful partnership with a custom heatsink manufacturer. Establish clear communication channels and protocols from the outset. This includes regular meetings, progress reports, and prompt responses to inquiries.

Here is a review from the customer:

| Information | Contents |

| Pros | Exceptional quality, excellent customer service, on-time delivery. |

| Cons | Higher price compared to some competitors, longer lead times for complex designs. |

| Overall | Highly recommended for projects requiring high-quality custom heatsinks and reliable manufacturing processes. |

Curious where custom heatsinks shine? They’re more versatile than you might think. I’ve used them in surprising places.

I’ve found custom heatsinks essential in LED lighting, where heat management is critical. They also play a vital role in power electronics, aerospace, and even medical devices. The key is high-performance cooling in a specific form factor.

Custom heatsinks have found their way into a vast array of applications, each benefiting from the tailored cooling solutions they provide. Let’s explore some common and some less obvious applications where these custom-engineered components play a crucial role.

LED lighting is revolutionizing the way we illuminate our world, but these efficient light sources aren’t without their challenges. LEDs generate heat, and managing that heat is essential for maintaining their performance and extending their lifespan.

Custom heatsinks are often used in LED lighting to dissipate heat away from the LED chip. This helps to keep the LED cool, preventing it from overheating and degrading. By using a custom heatsink, manufacturers can optimize the performance and lifespan of their LED lighting products.

Power electronics, such as power supplies, inverters, and converters, are essential components in many electronic devices. These devices generate heat as they convert electrical energy from one form to another.

Custom heatsinks are used in power electronics to dissipate heat away from the power semiconductors. This helps to keep the devices cool, preventing them from overheating and failing. By using a custom heatsink, manufacturers can improve the reliability and performance of their power electronics products.

Aerospace applications demand high-performance, reliable components that can withstand extreme conditions. Custom heatsinks are often used in aerospace electronics to dissipate heat away from sensitive components.

These heatsinks are typically designed to be lightweight and compact, while still providing excellent thermal performance. They may also be designed to withstand vibration, shock, and other environmental factors.

Medical devices often require precise temperature control to ensure accurate and reliable operation. Custom heatsinks are used in medical devices to dissipate heat away from sensitive components, such as sensors and lasers.

These heatsinks may be designed to be biocompatible and sterilizable, meeting the stringent requirements of the medical industry. They may also be designed to be low-noise, minimizing disruption to patients and medical personnel.

Automotive electronics are becoming increasingly complex, requiring efficient cooling solutions to maintain performance and reliability. Custom heatsinks are used in automotive electronics to dissipate heat away from components such as engine control units (ECUs), transmission control units (TCUs), and infotainment systems.

These heatsinks may be designed to withstand the harsh conditions of the automotive environment, including extreme temperatures, vibration, and humidity. They may also be designed to be compact and lightweight, minimizing their impact on vehicle weight and fuel economy.

| Industry | Common Applications |

| LED Lighting | Street lights, architectural lighting, stage lighting, grow lights |

| Power Electronics | Power supplies, inverters, converters, motor drives |

| Aerospace | Avionics, radar systems, satellite communication equipment |

| Medical Devices | MRI scanners, CT scanners, X-ray machines, patient monitoring systems |

| Automotive | Engine control units (ECUs), transmission control units (TCUs), infotainment systems, electric vehicle (EV) charging stations |

Ever wondered how these custom heatsinks are actually made? It’s a fascinating process.

From my experience, it usually starts with a detailed design based on my specific needs. Then comes the material selection, often aluminum. Finally, the manufacturing process involves CNC machining, extrusion, or forging to create the final shape.

The journey from concept to reality for a custom aluminum heatsink involves a series of carefully orchestrated steps. Understanding this process can help you make informed decisions and ensure a successful outcome.

The manufacturing process begins with a detailed design. This design should specify the dimensions, shape, fin density, material, and surface finish of the heatsink.

The design process often involves thermal simulation to optimize the performance of the heatsink. This simulation can help to identify potential hotspots and areas where the design can be improved.

Aluminum is a popular choice for heatsinks due to its excellent thermal conductivity, light weight, and relatively low cost. However, there are many different aluminum alloys to choose from, each with its own unique properties.

The choice of aluminum alloy will depend on the specific requirements of the application. For example, if the heatsink needs to be strong and durable, an alloy with high tensile strength may be chosen. If the heatsink needs to be lightweight, an alloy with low density may be chosen.

Once the design and material have been selected, the manufacturing process begins. There are several different manufacturing processes that can be used to create custom aluminum heatsinks, including:

The surface finish of a heatsink can significantly impact its thermal performance. A rough surface finish can increase the surface area of the heatsink, improving its ability to dissipate heat.

There are several different surface finishes that can be applied to aluminum heatsinks, including:

Quality control is an essential part of the manufacturing process. Each heatsink should be inspected to ensure that it meets the specified dimensions, shape, and surface finish.

Here is a table about manufacturing process:

| Process | Description |

| CNC Machining | Versatile process for creating complex shapes with high precision. |

| Extrusion | Cost-effective process for creating heatsinks with long, uniform shapes. |

| Forging | Shaping metal using compressive forces, resulting in strong and durable heatsinks. |

| Die Casting | Injecting molten metal into a mold, suitable for high-volume production of complex shapes. |

Custom aluminum heatsinks are worth considering for demanding cooling needs. I believe that with proper research, you can find a solution tailored to your project.