Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

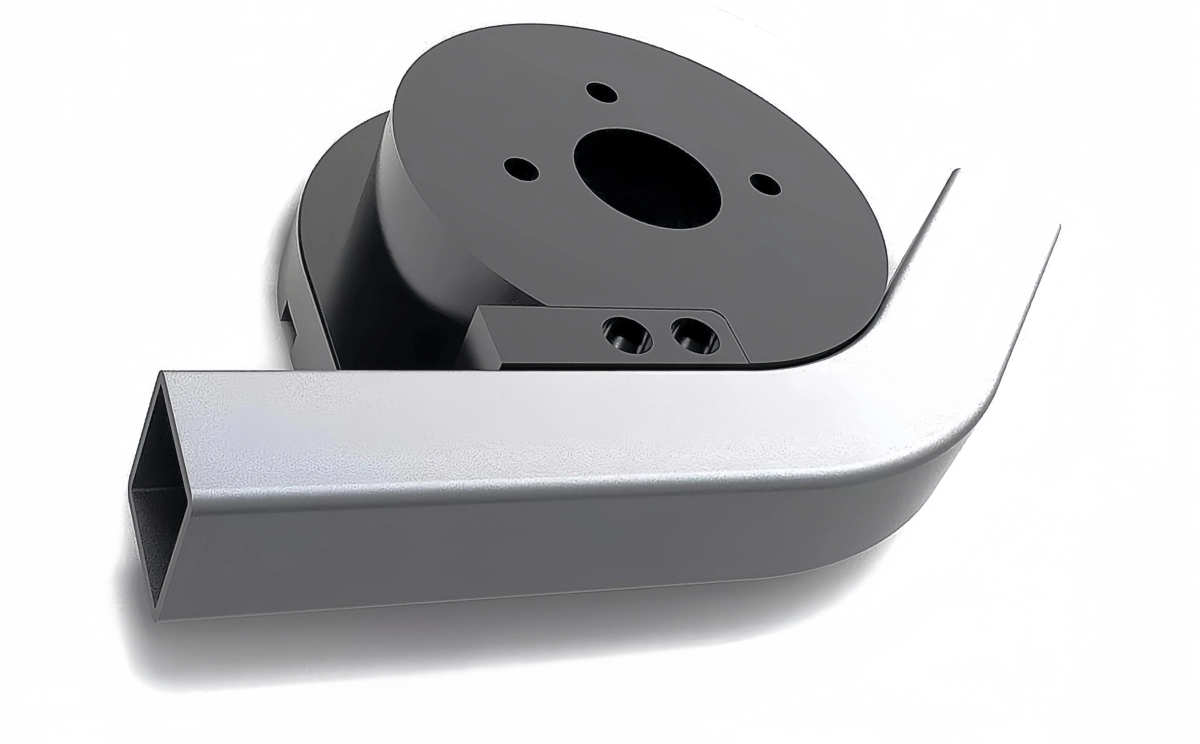

We bend all kinds of aluminum tubes here. Square tubing has its own challenges! What makes it special?

Bending aluminum square tubing requires careful consideration compared to round tubing. Maintaining the square shape and preventing distortion are key concerns. In my experience, specialized tooling and techniques are essential to achieving accurate and high-quality bends.

So, what makes bending aluminum square tubing different? Let’s explore!

What should we keep in mind when bending square aluminum tubing? Let’s discuss the specific challenges.

I think the biggest challenge is preventing the corners from collapsing or the sides from bowing. We need to distribute the bending force evenly and provide adequate support to maintain the square shape. The material properties also play a significant role.

Let’s dive deeper into the special considerations for bending aluminum square tubing. Understanding these challenges will help manufacturers develop effective strategies for achieving accurate and high-quality bends.

Maintaining the square shape is the primary concern when bending aluminum square tubing.

Distributing the bending force evenly is essential for preventing distortion.

| Technique | Description | Benefit |

| Proper Tooling | Use specialized tooling designed for bending square tubing. | Provides uniform support and distributes the bending force evenly. |

| Controlled Pressure | Apply pressure gradually and evenly throughout the bending process. | Prevents localized stress concentrations that can lead to distortion. |

| Lubrication | Use a high-quality lubricant to reduce friction and allow the aluminum to slide smoothly over the tooling. | Minimizes stress and prevents the aluminum from sticking to the tooling. |

Providing adequate support and reinforcement is critical for preventing distortion.

The properties of the aluminum alloy affect its bendability and resistance to distortion.

In my factory, we carefully consider these special considerations when planning aluminum square tubing bending projects. We work closely with our clients to ensure that the designs are feasible and that the final products meet their requirements.

What tools help us bend square aluminum tubing without causing it to distort? I’ll explain the key tooling.

I think specialized dies, mandrels, and pressure pads are essential for preventing distortion. The right tooling provides support and distributes the bending force evenly, ensuring a smooth and accurate bend. Investing in quality tooling is crucial for achieving consistent results.

Let’s dive deeper into the tooling that prevents distortion when bending aluminum square tubing. Selecting and using the right tooling is essential for maintaining the shape and integrity of the tubing during bending.

Specialized bending dies are designed to provide uniform support and distribute the bending force evenly across the square tubing.

Internal mandrels provide support from the inside of the square tubing, preventing the corners from collapsing and the sides from bowing.

| Mandrel Feature | Description | Benefit |

| Segmented Design | The mandrel is made up of multiple segments that can move independently. | Allows the mandrel to conform to the changing shape of the tube during bending. |

| Lubrication Groove | The mandrel has a groove that allows for lubrication. | Reduces friction and prevents the mandrel from sticking to the tube. |

| Material | Mandrels are typically made from hardened steel or brass. | Provides strength and durability. |

Pressure pads apply force to the outside of the square tubing, helping to maintain its shape and prevent distortion.

Other tooling considerations can help prevent distortion.

In my factory, we invest in high-quality, specialized tooling to ensure that we can consistently produce accurate and high-quality aluminum square tubing bends. We also train our operators to properly use and maintain the tooling.

How does the thickness of the tube walls affect the bending process? Let’s consider wall thickness.

I think the wall thickness is a critical factor. Thicker walls are more resistant to distortion but require more force to bend. Thinner walls are easier to bend but are more prone to collapsing or wrinkling. Choosing the right wall thickness is essential for achieving a successful bend.

Let’s dive deeper into how wall thickness affects bending aluminum square tubing. Understanding this relationship is key for selecting the appropriate material and bending parameters.

Wall thickness has a significant impact on the likelihood of distortion during bending.

The minimum bend radius that can be achieved without distortion is related to the wall thickness.

| Wall Thickness | Typical Minimum Bend Radius |

| Thin | Can be bent to a tighter radius. |

| Thick | Requires a larger bend radius. |

As a general rule, the minimum bend radius should be at least 1.5 times the tube’s width for thinner walls and up to 3 times the tube’s width for thicker walls.

The tooling requirements for bending aluminum square tubing are also affected by the wall thickness.

The aluminum alloy selected should also be considered in relation to the wall thickness.

The lubrication needs for bending aluminum square tubing are also influenced by the wall thickness.

In my factory, we carefully consider the wall thickness when planning aluminum square tubing bending projects. We also work closely with our clients to select the appropriate wall thickness for their specific application.

How can we keep the weld seams straight when bending square aluminum tubing? Let’s discuss this common problem.

I think the key is to position the weld seam correctly relative to the bending force. We also use specialized techniques to support the weld seam during bending and prevent it from collapsing or distorting. Careful control of the bending process is essential.

Let’s dive deeper into how to minimize weld seam distortion in bent square aluminum tubing. Preserving the integrity of the weld seam is crucial for maintaining the structural integrity and appearance of the finished product.

The position of the weld seam relative to the bending force has a significant impact on distortion.

Specialized support techniques can help prevent weld seam distortion during bending.

| Technique | Description | Benefit |

| Internal Mandrels | Use internal mandrels to provide support from the inside of the tube. | Prevents the weld seam from collapsing or distorting inward. |

| External Supports | Use external supports to prevent the weld seam from bowing outward. | Distributes the bending force evenly and minimizes stress on the weld seam. |

| Filler Materials | Fill the tube with a filler material, such as sand or resin, to provide internal support. | Helps maintain the shape of the tube and prevent weld seam distortion. |

Careful control of the bending process is essential for minimizing weld seam distortion.

The welding techniques used to create the weld seam can also affect its resistance to distortion during bending.

In my factory, we have developed specialized techniques for minimizing weld seam distortion in bent square aluminum tubing. We carefully consider the weld seam position, use appropriate support techniques, and maintain precise control of the bending process.

Bending square aluminum tubing demands precision. Correct tools and skills lead to success.