Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

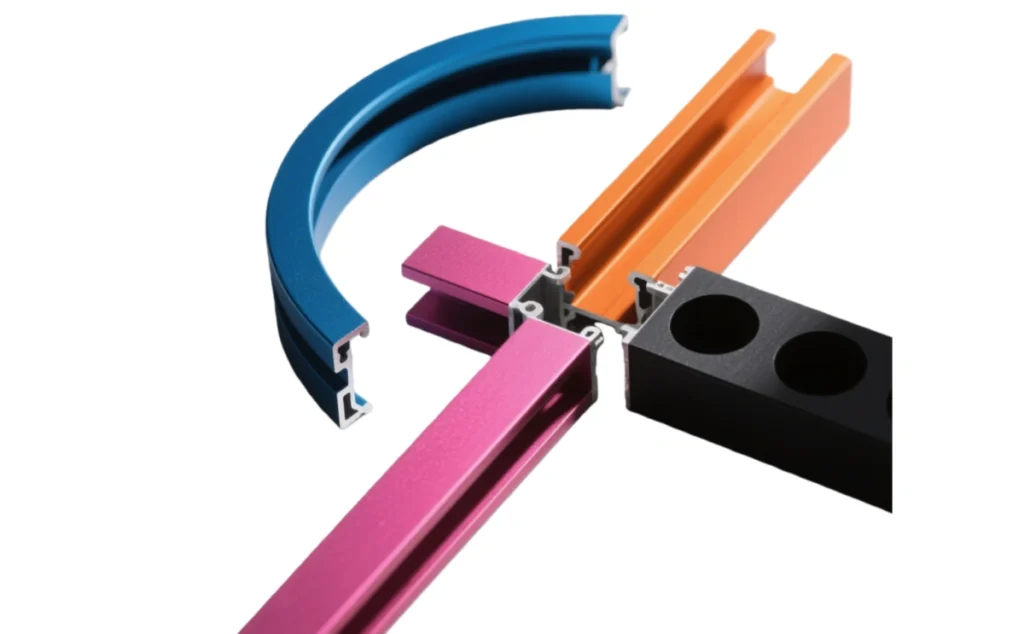

Aluminum profile bending technology has undergone a radical transformation. From traditional manual methods to the era of Precision CNC Stretch Bending and AI-driven simulations, the ability to shape aluminum without compromising its structural integrity is a cornerstone of modern engineering. This guide explores the cutting-edge technologies, innovative processes, and material sciences that are redefining what is possible in sectors like aerospace, automotive, and architectural design.

Aluminum is often hailed as the “metal of the future.” Its exceptional strength-to-weight ratio, natural corrosion resistance, and 100% recyclability make it indispensable. However, the true value of aluminum is unlocked through fabrication—specifically, the ability to bend extruded profiles into complex, high-performance shapes.

Aluminum profile bending technology is no longer just about changing the direction of a metal bar. It is a sophisticated discipline that balances material science, mechanical engineering, and digital precision. As industries demand tighter tolerances and more complex geometries, the evolution of bending techniques—specifically stretch bending—has become the driving force behind the next generation of skyscrapers and electric vehicles (EVs).

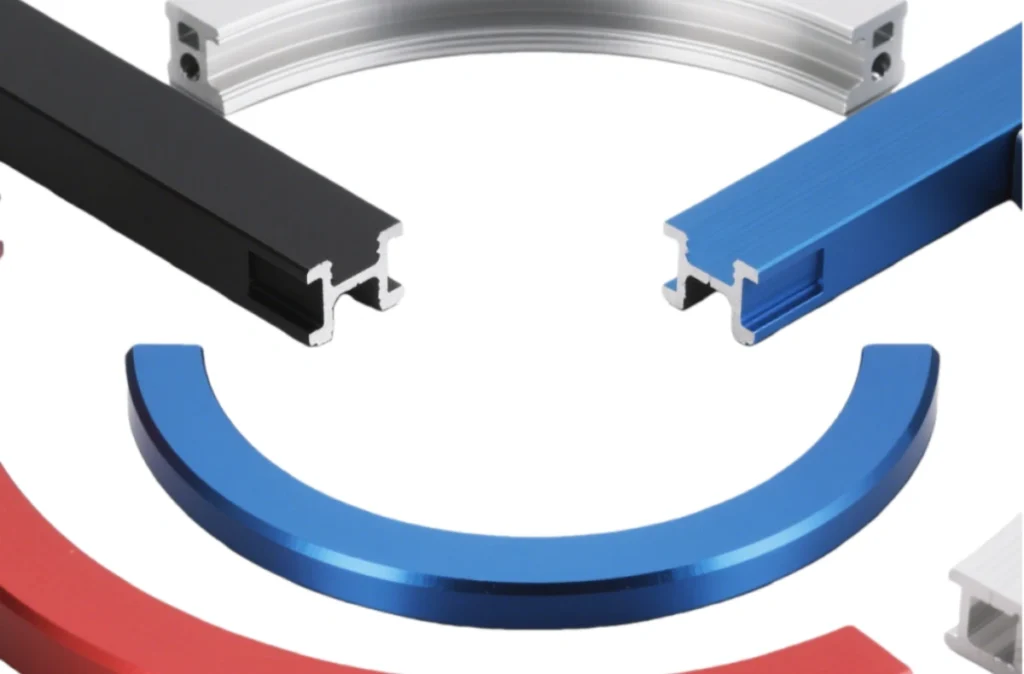

While there are many ways to bend aluminum (roll bending, press bending, rotary draw bending), Stretch Bending stands out as the most critical technique for industrial-grade profiles.

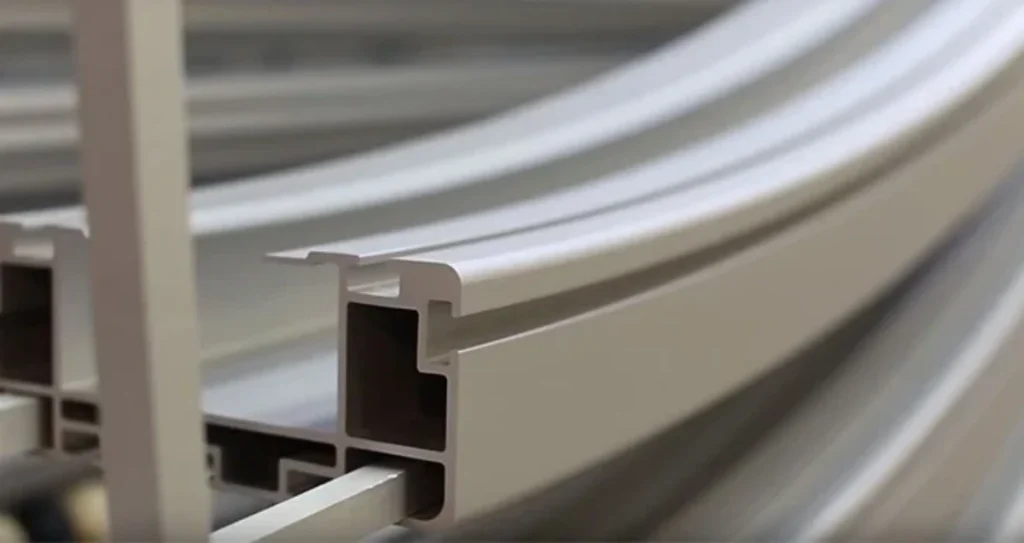

Stretch bending involves placing the aluminum profile under tension (stretching it to its yield point) while simultaneously wrapping it around a die or form block.

The integration of digital tools has transitioned aluminum bending from a “craft” to a “science.”

Computer Numerical Control (CNC) has revolutionized the workshop. Modern CNC stretch bending machines are multi-axis powerhouses.

Before a single piece of aluminum is touched, engineers use FEA (Finite Element Analysis) to simulate the bending process.

We are entering the era of Industry 4.0. Smart bending machines are now equipped with an array of sensors that monitor:

Beyond the standard stretch bend, several specialized processes have emerged to tackle unique engineering challenges.

Incremental bending is a “dieless” or “limited-die” technique. Instead of a single large mold, the machine uses a universal tool to apply small, localized deformations gradually.

Some high-strength aluminum alloys (like the 7000 series used in aerospace) are brittle at room temperature. Warm forming involves heating the profile—usually below the recrystallization temperature—to increase ductility.

Hydroforming uses high-pressure fluid to shape the aluminum profile against a mold.

The future of bending isn’t just about the machines; it’s about the metal itself.

Traditional alloys like 6061-T6 are versatile, but they can be challenging to bend due to their hardness. New research is focused on:

In aviation, every gram counts. Aluminum stretch bending is used to create the “ribs” and “stringers” of the aircraft fuselage. These parts must be incredibly light yet capable of withstanding the immense pressure cycles of flight.

The iconic curved skylights and “wavy” glass facades of modern landmarks (like airports and stadiums) are supported by bent aluminum profiles. Precision is key here—if the aluminum frame is off by even a millimeter, the expensive glass panels will not fit.

EV manufacturers use aluminum extrusions for battery enclosures and “crash cans.” Stretch bending allows for the creation of lightweight, energy-absorbing frames that protect passengers and battery cells while maximizing the vehicle’s range.

Despite technological leaps, aluminum bending remains a challenging field.

Looking ahead, the aluminum bending industry is moving toward a closed-loop ecosystem.

Aluminum profile bending technology is the bridge between a designer’s imagination and a functional reality. From the precision of CNC-controlled stretch bending to the predictive power of FEA simulations, the industry is more capable than ever of producing complex, high-strength components.

As we move toward a more sustainable and technologically integrated world, the ability to shape aluminum with efficiency and precision will remain a cornerstone of industrial progress. Whether it’s a structural component for a Mars-bound rocket or the sleek curve of a city’s new landmark, aluminum bending technology is the silent force shaping our world.

Q1: What is the main difference between roll bending and stretch bending?

A: Roll bending uses three rollers to curve a profile and is great for continuous circles. Stretch bending pulls the material while bending, which is far superior for preventing wrinkles and maintaining cross-sectional shape in complex profiles.

Q2: Can all aluminum alloys be bent?

A: Most can, but the “temper” matters. T4 is generally the best for bending, while T6 is harder and may require heating (warm forming) to prevent cracking.

Q3: How does CNC technology reduce costs?

A: It reduces labor, minimizes scrap through high accuracy, and allows for faster production cycles, making it more cost-effective for both medium and high-volume runs.

Q4: Why is FEA important for aluminum bending?

A: FEA allows engineers to “fail fast” in a virtual environment. It saves money by identifying potential production issues before any physical metal is wasted.

SEO Keywords: Aluminum profile bending technology, stretch bending, CNC aluminum bending, FEA simulation in metal forming, aluminum extrusion fabrication, aerospace aluminum bending, architectural aluminum curves, smart bending machines, hydroforming aluminum.

Meta Description: Explore the future of aluminum profile bending technology. From precision CNC stretch bending to AI-driven FEA simulations, learn how innovative processes are reshaping the aerospace, automotive, and architectural industries.